Taking Custom Design to New Levels

PROUD TO BE PART OF THE BRIN FAMILY OF COMPANIES

OTHER BRIN LOCATIONS

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

In today's fast-paced industrial landscape, efficiency is paramount. AGV robots, or Automated Guided Vehicles, are revolutionizing the way businesses operate. They streamline workflows and minimize human error. Many companies face daily challenges, such as labor shortages and increasing operational costs. AGV robots address these issues head-on.

Imagine a warehouse where goods move seamlessly. AGV robots navigate through aisles, transporting materials without human intervention. Their adaptability shines in various environments. However, implementing such technology is not without hurdles. Initial investment can be daunting for some businesses. Also, the integration process may require adjustments to existing systems. Reflecting on these challenges can lead to a more informed decision.

Ultimately, the choice to adopt AGV robots is about weighing benefits against potential obstacles. While they offer remarkable advantages, understanding the intricacies of their deployment is crucial. Businesses must consider their unique needs before taking the leap into automation.

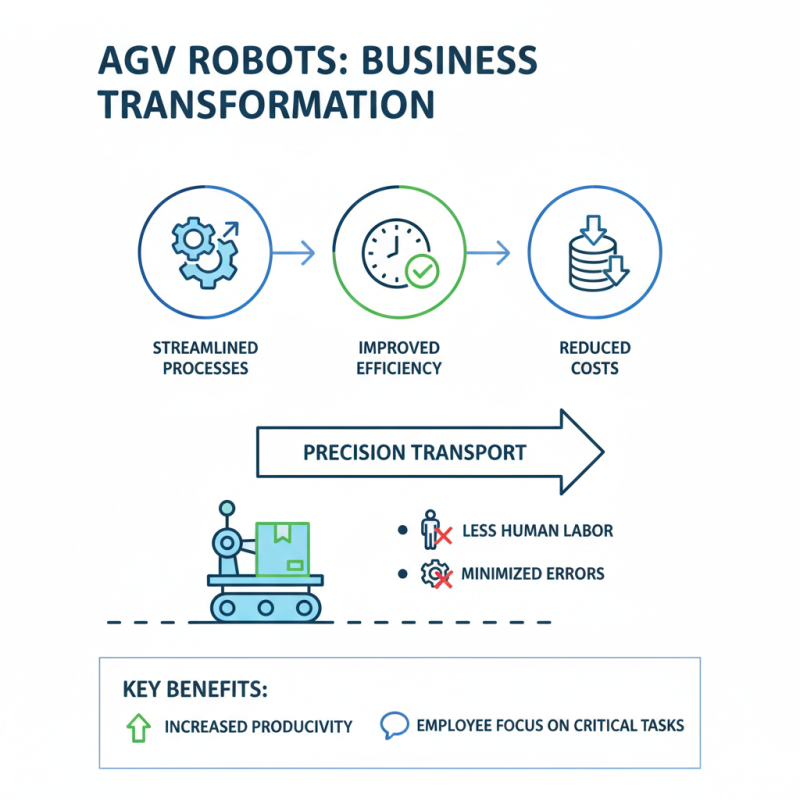

AGV robots are transforming the way businesses operate. These automated guided vehicles streamline processes, improve efficiency, and reduce operational costs. By navigating warehouses and production floors, they can transport goods with precision. This reduces human labor and minimizes errors. Employees can focus on more critical tasks, increasing overall productivity.

One significant advantage is the ability to operate around the clock. AGV robots don’t require breaks or rest. They consistently perform tasks, ensuring more goods are moved in less time. However, there can be challenges. Integrating these robots into existing systems may require adjustments. Companies must ensure that their layouts allow for effective navigation.

Another point worth considering is maintenance. AGV robots do need regular check-ups. It's essential to have a plan in place for any potential downtime. Organizations should be ready to address these factors to maximize the benefits of automation. While the advantages are clear, careful implementation and ongoing management are critical for success.

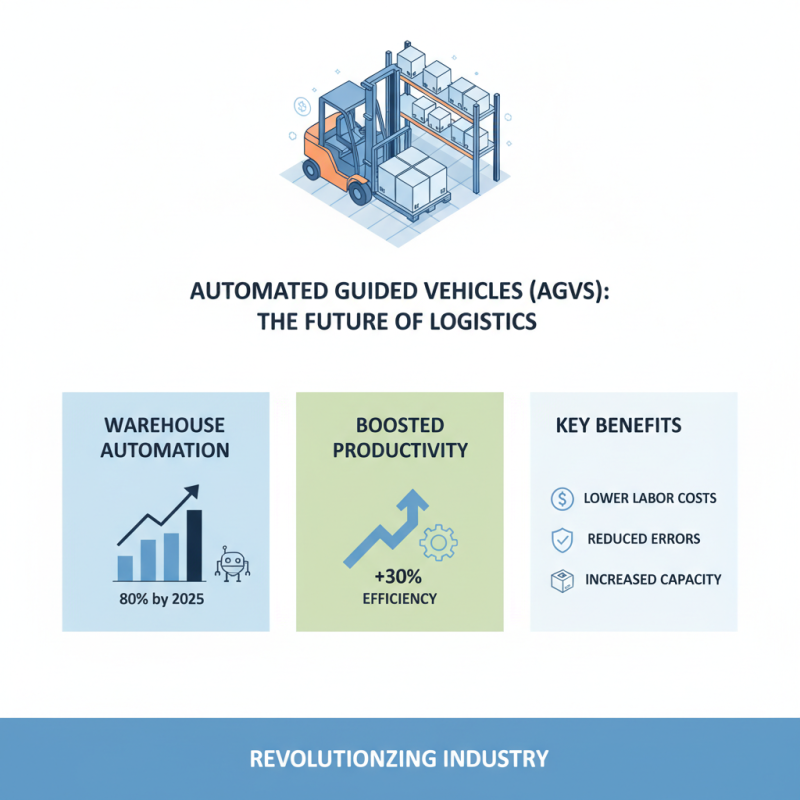

Automated Guided Vehicles (AGVs) are revolutionizing various industries. Warehousing and logistics are primary sectors that see huge benefits. Nearly 80% of warehouses are expected to automate by 2025. AGVs can boost productivity by up to 30%. They reduce labor costs and minimize human errors too. This tech allows companies to handle more inventory.

Manufacturing is another critical area. AGVs streamline the production process, cutting down cycle times. In some facilities, production efficiency has improved by up to 25% after integrating AGVs. However, not all facilities have adopted AGVs yet. Many businesses still rely on manual labor. This choice often leads to bottlenecks and inefficiencies.

Tips: Start small. Consider pilot programs before full implementation. Monitor performance closely. Take time to analyze data and gather insights. This reflection is crucial for optimizing AGV usage. The healthcare sector is also witnessing the rise of AGVs. They transport medication and supplies, enhancing patient safety. Automation simplifies complex tasks, allowing staff to focus on patient care. Yet, not every healthcare facility is on board. There could be fears about reliability and job displacement. Balancing technology and human roles remains a challenge.

AGV robots are transforming how businesses operate. They streamline processes, reduce manual labor, and increase efficiency. These autonomous vehicles transport goods throughout facilities with precision. Imagine a warehouse where products move effortlessly from point A to point B. AGV robots handle this task, allowing human workers to focus on more complex duties.

The integration of AGV robots can lead to significant productivity gains. Workers experience fewer accidents and reduced fatigue. However, implementing these systems isn't without challenges. Companies must consider the initial investment and ongoing maintenance. Training staff to work alongside robots can also be a hurdle.

Adopting AGV technology brings undeniable benefits. Still, it requires careful planning and consideration. Balancing automation with human expertise is essential. Efficiency rises, yet businesses should reflect on how to maximize these advancements. Are they leveraging the full potential of AGV robots? There’s always room for improvement.

When considering AGV technology for your business, several factors come into play. The environment where robots will operate is crucial. For example, indoor settings can be more predictable compared to outdoor locations. Examine the facility layout carefully. An obstacle-free path is vital for the optimal performance of AGVs.

Training staff is another key factor. Employees must understand how to work alongside robots. Their comfort level can affect productivity. Clear communication about tasks and safety protocols is necessary. Also, ongoing training sessions can help keep everyone updated.

**Tips:** Start with a pilot project. This allows for adjustments based on real-world experiences. Gather feedback from staff during this phase. Make small changes before a full rollout. Another tip is to assess the ROI early on. This helps in understanding the technology's impact. Analyze whether the investment truly enhances efficiency or just adds complexity.

AGV robots, or Automatic Guided Vehicles, are revolutionizing various industries. Their future trends indicate a significant shift towards advanced technologies. Artificial intelligence and machine learning are shaping their development. These innovations enable AGVs to adapt to changing environments. They can now navigate complex pathways more efficiently.

Tips: Consider integrating AGV robots gradually. Start with a smaller fleet to assess performance. Monitor their impact on productivity. This helps in evaluating their real benefits.

Collaborative robots will also play a key role. AGVs will work alongside human workers more effectively. They will handle repetitive tasks, allowing humans to focus on complex ones. However, there are challenges. Adjusting to new workflows can be difficult. Employees may need training to ensure smooth cooperation.

Tips: Communication is essential. Keep your team informed about changes. Encourage feedback to improve the integration process. Addressing concerns early can ease transitions.

| Feature | Description | Benefits | Future Trends |

|---|---|---|---|

| Navigation Technology | Utilizes advanced sensors and mapping | Improved efficiency and accuracy in routing | Integration of AI for smarter navigation |

| Payload Capacity | Varied capacities for different applications | Flexibility in handling various materials | Development of heavier-duty models |

| Charging Methods | Inductive and fast charging options | Reduced downtime and improved productivity | Wireless charging and battery technology advancements |

| Safety Features | Equipped with collision detection and emergency stops | Enhanced safety for workers and environments | Increased autonomy and AI-driven safety systems |

| Data Integration | Connects with existing management systems | Seamless operations and real-time monitoring | Greater use of big data for optimization |

Taking Custom Design to New Levels

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

Fabricator

Inside Sales and Client Support Manager

Glass Handler – 1st Shift