Taking Custom Design to New Levels

PROUD TO BE PART OF THE BRIN FAMILY OF COMPANIES

OTHER BRIN LOCATIONS

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

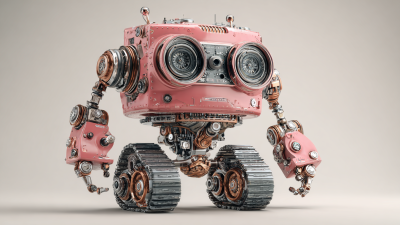

In the rapidly evolving landscape of modern manufacturing, the integration of advanced robotics has become paramount for enhancing efficiency and precision. Among these innovations, the 6 axis robot arm stands out due to its versatility and adaptability across a myriad of applications—from assembly and welding to packaging and material handling. According to a recent report from the International Federation of Robotics (IFR), the implementation of industrial robots, particularly 6 axis systems, is projected to increase by 15% annually, with businesses increasingly acknowledging their role in optimizing production processes. This growth reflects a broader trend towards automation, where companies can reduce operational costs and improve product quality. By harnessing the capabilities of 6 axis robot arms, manufacturers position themselves to meet the demands of an ever-competitive market while ensuring scalability and innovation in their operations.

In recent years, the integration of 6 axis robot arms in manufacturing processes has revolutionized operational efficiency and precision. A report by MarketsandMarkets projected that the global industrial robotics market will reach $75.5 billion by 2025, driven largely by advancements in robotics technology and the increasing adoption of automation across various sectors. One significant advantage of 6 axis robot arms lies in their ability to perform complex tasks with high precision, facilitating processes such as welding, painting, and assembly. Their flexibility allows manufacturers to adapt to varying production requirements without extensive reconfiguration.

Moreover, 6 axis robot arms can significantly boost productivity and reduce labor costs. According to a study by the International Federation of Robotics, companies that integrated advanced robotics reported an average productivity increase of 30%. The ability of these robots to operate continuously, coupled with their accuracy in executing repetitive tasks, minimizes downtime and enhances overall production capacity. As manufacturers strive to remain competitive in a dynamic market, the adoption of 6 axis robot arms is not just an advantage but a strategic necessity for future growth and innovation.

The versatility of 6-axis robot arms has revolutionized modern manufacturing, offering remarkable flexibility that caters to diverse operational needs. One of the key features enhancing their adaptability is the articulated design, which allows for an extensive range of motion, mimicking the natural movement of a human arm. This capability enables these robots to perform complex tasks such as assembling intricate components, packaging products, and conducting quality inspections with precision and speed.

Another significant attribute is their programming flexibility. With advanced software interfaces and user-friendly programming tools, manufacturers can easily customize robot operations to meet specific production requirements. This adaptability not only optimizes workflow but also allows for quick reconfiguration when product lines change. Additionally, integrating artificial intelligence and machine learning capabilities into these 6-axis arms empowers them to learn from their environment, making real-time adjustments and improving overall efficiency. Ultimately, these features position 6-axis robots as invaluable assets in the pursuit of efficiency and innovation within modern factories.

| Feature | Description | Benefit |

|---|---|---|

| High Precision | Ability to perform tasks with accuracy within microns | Improves product quality and reduces waste |

| Versatile End Effectors | Interchangeable tools for various tasks like welding, grasping, and painting | Enhances flexibility in production lines |

| Compact Design | Space-efficient design allowing use in limited spaces | Maximizes workspace while maintaining productivity |

| Real-time Feedback | Integrated sensors that provide immediate operational data | Facilitates quick adjustments and enhances operational efficiency |

| Easy Programming | User-friendly software interfaces for programming tasks easily | Reduces setup time and increases versatility |

| Safety Features | Built-in safety protocols and sensors | Protects operators and machinery, allowing for collaborative workspaces |

The versatility of 6-axis robot arms in modern manufacturing is evident across a variety of industries, ranging from automotive to pharmaceuticals. According to a report by MarketsandMarkets, the global market for industrial robots is expected to reach $61 billion by 2025, with 6-axis robots accounting for a significant share due to their flexibility and efficiency. In the automotive sector, for example, 6-axis robots streamline assembly lines, enabling precise manipulation of components, which can enhance production speeds by up to 30%. This precision reduces waste and improves overall product quality.

In the electronics manufacturing industry, 6-axis robot arms are employed for tasks like soldering and assembly of delicate components, handling materials too small for human hands while maintaining exceptional accuracy. The International Federation of Robotics indicates that in 2021, robotics use in electronics grew by over 20%, driven primarily by the demand for higher productivity and improved safety for workers.

Tips for industries considering the implementation of 6-axis robots include investing in proper training for operators to harness the full capabilities of the technology. Additionally, companies should evaluate their specific production needs to determine the optimal robot configurations and programming options, ensuring seamless integration into existing workflows. By doing so, businesses can maximize the return on investment and stay competitive in an increasingly automated market.

The integration of 6-axis robot arms in modern manufacturing applications is a game changer, offering unparalleled flexibility and precision. These robots, capable of intricate movements, enhance workflow efficiency while significantly reducing operational costs. According to recent industry reports, the deployment of robotic arms is expected to grow by over 25% annually, reflecting the growing reliance on automation in diverse sectors, from automotive to electronics.

To ensure seamless workflow and productivity, organizations can adopt several best practices when integrating 6-axis robots into their operations. First, thorough training for staff on utilizing robotic systems is essential, as it maximizes both productivity and safety on the manufacturing floor. Additionally, employing advanced software for real-time monitoring enables companies to swiftly adjust operations and resolve potential bottlenecks. Furthermore, maintaining regular robotic maintenance schedules can prevent downtime, ensuring that production remains uninterrupted.

These strategic approaches, combined with the latest in robotic technology, empower companies to embrace automation effectively, leading to enhanced operational productivity and competitiveness in an ever-evolving market landscape.

The versatility of 6-axis robot arms in modern manufacturing applications is set to be a key driver in the industry's evolution, particularly as we look towards future trends and innovations in robotics technology. According to industry reports, the global robotics technology market is projected to reach USD 237.0 billion by 2033, growing at a compound annual growth rate (CAGR) of 9.13%. This remarkable growth reflects the increasing reliance on advanced automation to enhance efficiency and precision across various manufacturing processes.

One of the most significant innovations in this space is the integration of AI and IoT technologies, which are paving the way for smarter industrial automation. With the emergence of robotic systems capable of learning and adapting to complex tasks, the functionality of 6-axis robots is expanding beyond traditional applications. As these machines become more intuitive, manufacturers can expect a reduction in operational costs and an increase in overall productivity.

Tip: To stay ahead in the competitive landscape, manufacturers should invest in R&D and explore partnerships with robotics firms that focus on cutting-edge technologies.

Moreover, as the demand for customization rises, 3D printing technologies are playing a pivotal role in revolutionizing manufacturing. The ability to produce tailored solutions on-demand is transforming traditional supply chains and enabling manufacturers to respond swiftly to market needs.

Tip: Embrace innovative materials and production techniques to enhance your product offerings and meet evolving consumer expectations.

Taking Custom Design to New Levels

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

Fabricator

Inside Sales and Client Support Manager

Glass Handler – 1st Shift