Taking Custom Design to New Levels

PROUD TO BE PART OF THE BRIN FAMILY OF COMPANIES

OTHER BRIN LOCATIONS

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

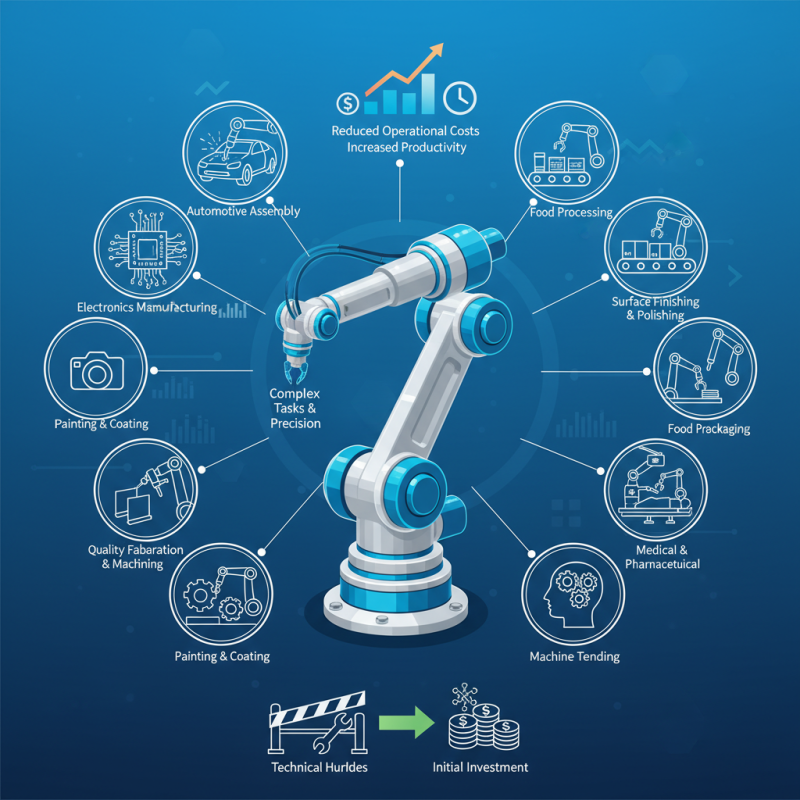

In today's fast-paced world, the role of the 6 axis robot in various industries is crucial. Expert John Smith, a leading figure in automation technology, once said, "6 axis robots are redefining efficiency and precision in manufacturing." This statement captures the essence of their impact in sectors like automotive, electronics, and food processing.

These versatile machines can handle complex tasks with remarkable speed and accuracy. For instance, in automotive assembly, a 6 axis robot can perform intricate welding work that would be challenging for humans. In electronics, they ensure the delicate placement of components with utmost care. Yet, the integration of these robots may come with hurdles. Technical issues can arise, and the initial investment might be daunting for smaller companies.

However, the benefits often outweigh these concerns. Many industries report reduced operational costs and increased productivity. As companies explore automation, the 6 axis robot proves to be a game changer—transforming not only how work is done but also shaping the future of manufacturing.

In today's manufacturing landscape, 6-axis robots play a vital role in automation. They can perform various tasks with precision and flexibility. For instance, these robots are used for welding, assembly, and painting. Their ability to reach multiple angles makes them ideal for complex tasks. This versatility helps streamline processes and reduce labor costs.

When implementing 6-axis robots, it's essential to consider their programming. Proper training for operators is necessary. A well-programmed robot can increase efficiency significantly. However, poor programming can lead to errors and downtime. It's important to invest in quality training and continual support.

Tip: Always monitor robot performance. Tracking their efficiency helps identify potential issues early.

Another area where 6-axis robots excel is in material handling. They can manage heavy loads and perform repetitive tasks, which reduces strain on human workers. However, relying solely on automation might lead to challenges. Over-dependence on robots can result in skill gaps in the workforce. Balancing human and robot collaboration is key.

Tip: Regularly assess the impact of automation on your team. This ensures a harmonious work environment that benefits everyone.

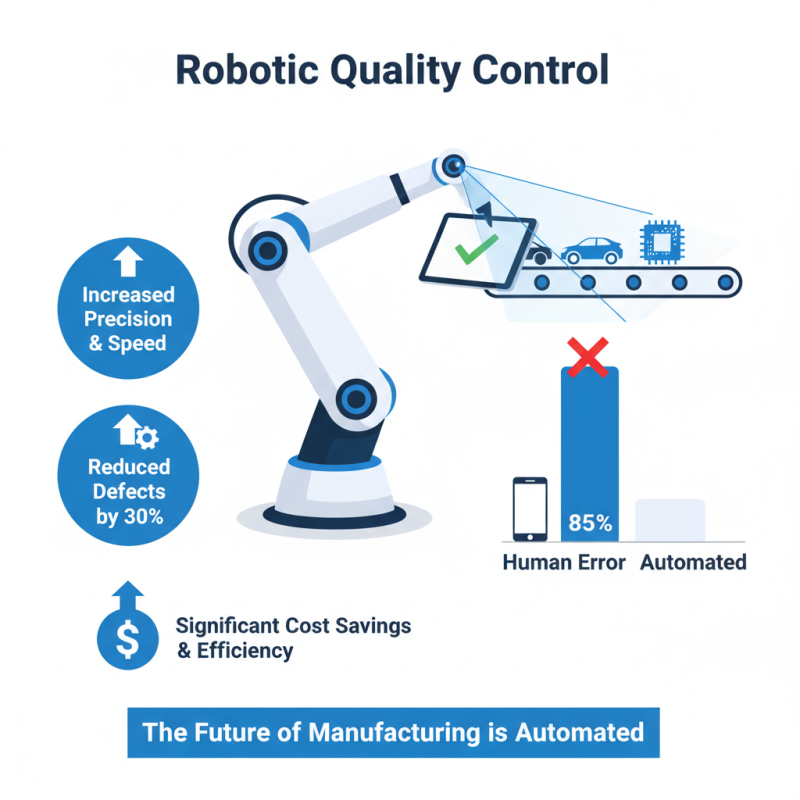

In production lines, 6 axis robots are transforming quality control. These robots increase precision and speed, ensuring products meet strict standards. A recent report indicates that 85% of manufacturing errors arise from human intervention. Automating these processes can reduce defects by up to 30%. This leads to significant cost savings and boosts overall efficiency.

Implementing 6 axis robots allows for consistent monitoring. They can quickly identify discrepancies in production. This technology can analyze data in real-time. It helps in making necessary adjustments instantly. However, companies must train staff to understand these changes. A lack of communication often leads to misunderstandings and unresolved issues.

**Tip:** Regularly assess the performance of these robots. Identify areas where human oversight is still necessary. Balancing automation with human insights can enhance effectiveness. Also, invest in continuous training for your team. This ensures everyone adapts to technological advancements smoothly.

6 axis robots have transformed the automotive industry significantly. They handle complex tasks with precision. Their versatility is unmatched, making them ideal for assembly lines. According to a report by the International Federation of Robotics, automotive manufacturers increasingly rely on these robots. In fact, over 60% of industrial robots are used in automotive production.

Assembly processes have become faster and more efficient. 6 axis robots can perform welding, painting, and even inspecting parts. They ensure uniformity in production. This reduces the chances of human error. However, the transition to automation has not been seamless. Some workers face job displacement. Retraining programs are vital to mitigate these challenges.

Production data shows that companies leveraging 6 axis robots increased output by 20% on average. Yet, adaptation can take time. Companies must analyze costs versus benefits thoroughly. Investing in these robotic systems requires careful planning. The integration process can be complex, and not all manufacturers succeed. A flexible approach helps in navigating these hurdles.

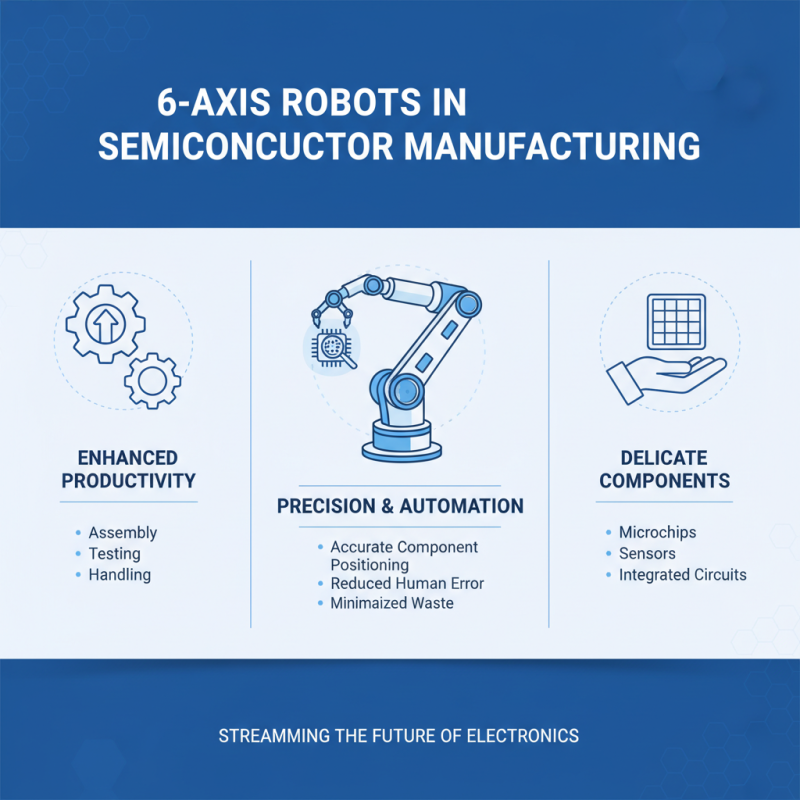

In the realm of electronics and semiconductor manufacturing, 6 axis robots play a vital role. These robots enhance productivity immensely. They are designed to handle delicate components with precision. Tasks like assembly, testing, and handling are streamlined through automation. For instance, during chip assembly, these robots can position components accurately. They minimize human error and reduce waste.

However, the reliance on 6 axis robots presents challenges. They may struggle with complex tasks that require adaptive thinking. Additionally, integrating these robots into existing workflows can be complicated. Some manufacturers report issues with after-sales support and maintenance. Proper training for operators is crucial to ensure maximum efficiency. Without it, the robots may not perform as intended.

Furthermore, safety is a persistent concern in these environments. While robots reduce physical strain on human workers, they can also pose risks. Collaborative robots often require careful programming to function safely alongside humans. There are instances where miscommunication leads to accidents. Reflection on these aspects is essential for future advancements.

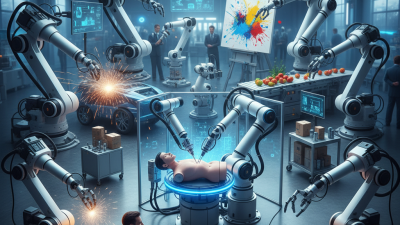

The impact of 6 axis robots in medical applications is significant. They improve accuracy in surgical procedures. Research indicates that these robots can increase precision by over 30% compared to manual surgery. This enhancement minimizes patient recovery time. Reduced complications lead to better outcomes.

In hospitals, these robots assist in tasks like tissue manipulation and suturing. One report states that 80% of surgeons believe robotic assistance enhances their abilities. However, there are challenges. Not all medical staff feels comfortable using this technology. Training is essential but often overlooked. Some doctors express concerns about relying too heavily on automation.

Moreover, the cost of implementing these robots can be a barrier. Many facilities struggle to justify the investment. A study found that only 60% of hospitals have adopted this technology fully. Ultimately, while 6 axis robots are revolutionizing the medical field, there is still room for improvement in their integration and training across the industry.

Taking Custom Design to New Levels

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

Fabricator

Inside Sales and Client Support Manager

Glass Handler – 1st Shift