Taking Custom Design to New Levels

PROUD TO BE PART OF THE BRIN FAMILY OF COMPANIES

OTHER BRIN LOCATIONS

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

The field of robotic arm design is evolving rapidly. According to the International Federation of Robotics, the market for industrial robots is projected to reach $70 billion by 2026. This surge in innovation spurs designers to explore new capabilities. Expert Dr. Emily Zhang, a leading voice in robotic technology, stated, "Robotic arms will redefine manufacturing efficiency in the coming years."

Emerging trends in robotic arm design focus on enhanced precision and flexibility. Companies are harnessing advanced materials and AI integration to enhance functionality and durability. These developments promise a future where robotic arms play a vital role in various sectors. However, challenges remain. High development costs and complex programming can limit accessibility.

Despite these hurdles, the industry pushes forward. Innovative designs are paving the way for smarter and more adaptive robotic solutions. As we delve into the top innovations in this realm, it is essential to reflect on both the potential and the obstacles that lie ahead.

The emergence of robotic arms in modern technology is transforming various industries. According to a report by MarketsandMarkets, the global robotic arms market is projected to reach $20 billion by 2025, growing at a CAGR of 12% from 2020. This rise highlights how automation is becoming crucial in sectors like manufacturing and healthcare. Robotic arms can enhance precision in tasks like assembly and surgery, reducing human error significantly.

However, this rapid integration poses challenges. While robotic arms improve efficiency, they also raise concerns over job displacement. A study by McKinsey states that automation could displace over 800 million jobs globally by 2030. Not all robots can meet the unique needs of different tasks. Many designs still struggle with adaptability. The evolution of these machines presents both opportunities and obstacles. Ongoing research is essential. Designers must focus on creating more flexible robotic arms that can learn and adapt in real-time.

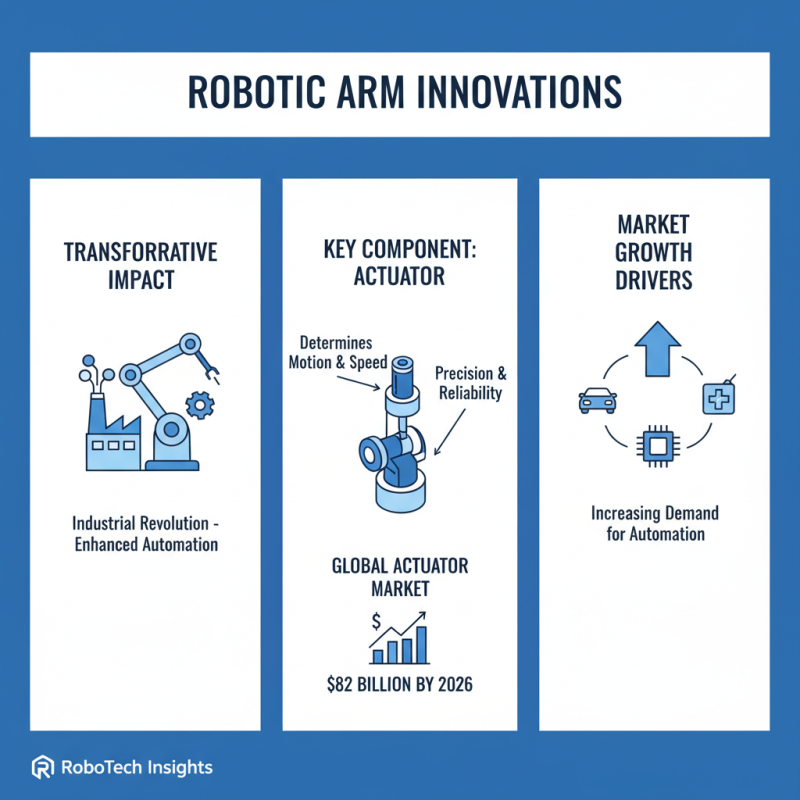

Robotic arms have transformed industries, boasting key innovations that enhance their capabilities. One major component is the actuator. Actuators determine the range of motion and speed of robotic arms. According to a report by MarketsandMarkets, the global actuator market is projected to reach $82 billion by 2026. This growth reflects the increasing demand for precise and reliable movements in automation.

Another vital element is the end effector. This component performs tasks like gripping or welding. Many designs focus on versatility. For example, soft robotics technology is gaining traction. A study from the Journal of Mechanisms and Robotics shows that soft robotic grippers can handle delicate objects better than traditional hard ones. However, scalability remains a challenge. Engineers often struggle to balance flexibility and strength in these designs.

Control algorithms are also crucial. They enable the robotic arm to respond accurately to its environment. As machine learning evolves, algorithms are becoming more sophisticated. Yet, according to a 2023 IEEE report, inconsistencies in performance still exist. Developers must continually refine algorithms to bridge these gaps. With ongoing innovations, the future holds great promise for robotic arms in various applications.

In recent years, the field of robotics has advanced significantly, especially in precision and control mechanisms. A report by MarketsandMarkets estimates that the global robotics market will reach $200 billion by 2026. This growth is driven by innovations in robotic arm designs. Improved algorithms enhance motion control, allowing for more accurate tasks. Robots can now execute complex movements with minimal errors.

Precision mechanics, such as servo motors, have transformed performance. Researchers reported that these motors can achieve position accuracy within 0.1 mm. This level of precision is crucial in industries like manufacturing and healthcare. Yet, as the technology evolves, challenges remain. Not all robotic arms can adapt to different tasks smoothly. Some face difficulties in real-time feedback, impacting efficacy.

Control systems also display notable improvements. Advanced sensors provide real-time data, allowing robotic arms to adjust movements on the fly. Still, better sensor integration is needed for enhanced responsiveness. A study revealed that outdated feedback loops limit flexibility. Some designs struggle under dynamic conditions, reflecting the need for further innovation. The journey toward perfecting robotic arm design continues as industry professionals seek to balance precision with adaptability.

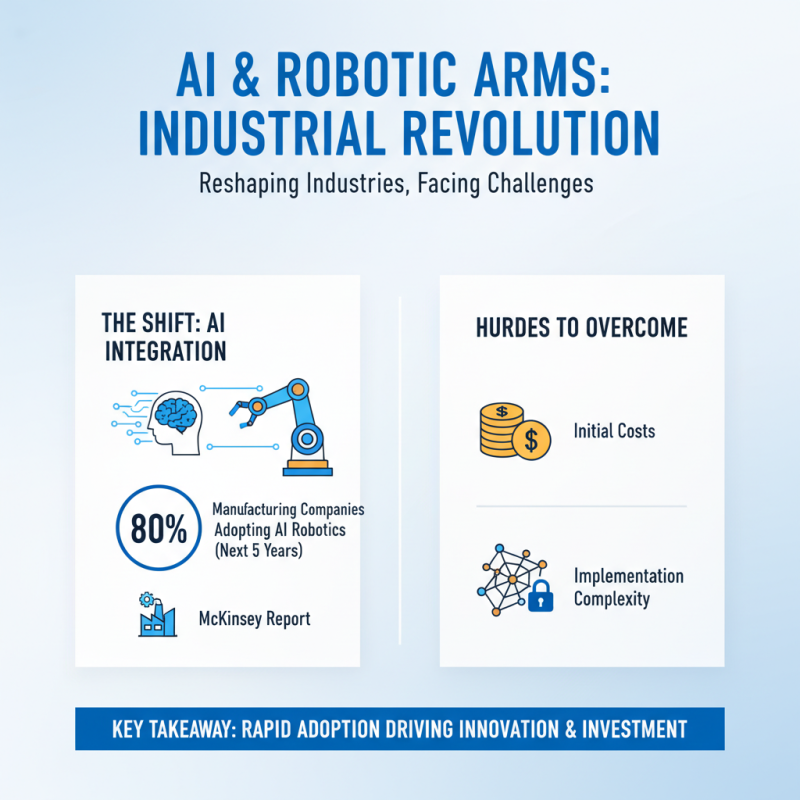

Advancements in AI integration for robotic arms are reshaping industries. According to a recent report by McKinsey, 80% of manufacturing companies plan to adopt AI-driven robotics within the next five years. This rapid integration is not without its challenges. Many companies struggle with the initial costs and complexity of implementing AI solutions.

AI-powered robotic arms can perform complex tasks. They learn from their environment and adapt to various scenarios. For instance, in assembly lines, these robots can adjust their actions based on the variability of tasks. However, they require extensive training datasets. Without quality data, their efficiency can decline. A study suggests that 55% of robotic implementations fail due to inadequate programming.

Moreover, safety remains a key concern as robots become more autonomous. The World Economic Forum indicates that 25% of jobs in manufacturing could be disrupted by AI and automation. This wave of change creates job uncertainty. Labor markets must adapt. Workers need retraining to collaborate effectively with AI-driven machines. Balancing automation and employment is crucial as industries move forward.

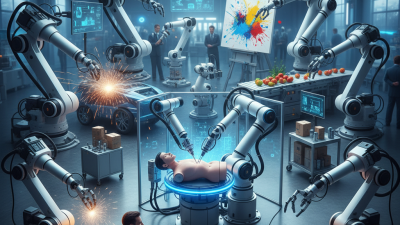

Innovative robotic arm designs are changing industries. They are essential in manufacturing, healthcare, and agriculture. A recent industry report indicates that the global robotic arm market is expected to reach $22 billion by 2026. This growth is driven by advancements in automation.

In manufacturing, robotic arms optimize production lines. They perform tasks like welding and assembly with high precision. However, integration can be a challenge. Companies often struggle with costs and training. In healthcare, robotic arms assist in surgeries, enhancing accuracy. Yet, there are concerns about reliance on technology. Medical professionals must ensure that these systems support, not replace, human judgment.

Agricultural robots are transforming farming practices. They help with planting, harvesting, and monitoring crops. Data shows that farms using robotic technology can boost yield by 20%. Still, there are limitations. Not all farms can afford this technology. Innovation must also consider sustainability and efficiency. Addressing these challenges is crucial for future advancements.

| Innovation | Key Features | Applications | Industry Impact |

|---|---|---|---|

| Adaptive Grippers | Flexible grasping, sensor integration | Assembly, packaging | Increased efficiency, reduced damage |

| Collaborative Arms | Safety features, user-friendly interfaces | Manufacturing, electronics | Enhanced human-robot collaboration |

| Modular Design | Interchangeable parts, scalable | Custom applications, education | Versatile solutions for diverse needs |

| Soft Robotics | Soft materials, adaptable movement | Food handling, delicate assembly | Improved safety for fragile objects |

| AI-Powered Control | Machine learning algorithms, predictive maintenance | Automotive, aerospace | Higher precision and reduced downtime |

| Teleoperation Systems | Remote control, real-time feedback | Healthcare, hazardous environments | Safer operations in dangerous scenarios |

| High-Speed Robotics | Rapid movements, accuracy | Logistics, high-volume manufacturing | Significant productivity boosts |

| Integrated Vision Systems | Real-time image processing, object recognition | Quality control, sorting | Improved accuracy in inspections |

| Self-Driving Robotic Arms | Autonomous operation, navigation | Warehouse automation, logistics | Streamlined workflows |

| Robotic Arm Simulation Software | 3D modeling, virtual testing | Design prototyping, training | Reduced design errors and costs |

Taking Custom Design to New Levels

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

Fabricator

Inside Sales and Client Support Manager

Glass Handler – 1st Shift