Taking Custom Design to New Levels

PROUD TO BE PART OF THE BRIN FAMILY OF COMPANIES

OTHER BRIN LOCATIONS

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

In today’s fast-paced world, industries are undergoing a significant transformation. Robotic automation is at the heart of this shift. Experts like Dr. Sarah Jensen, a leader in automation technology, stated, "Robotic automation creates opportunities for efficiency and capability enhancement." This highlights the profound impact robotics is having across various sectors.

Robotic automation streamlines processes and reduces manual workload. Many businesses have adopted these technologies to improve productivity. In manufacturing, robots handle repetitive tasks with precision, ensuring quality and consistency. However, implementing robotic automation comes with challenges. Companies must invest in training and adapt their workforce. This transition can be daunting for many organizations.

Moreover, not every company sees immediate success. Some struggle to integrate robotics effectively. Studies show that 30% of automation projects fail to meet their objectives. This calls for reflection on how to implement these advanced technologies. Robotic automation holds great potential, yet its implementation requires careful planning and evaluation. The journey is just beginning, and learning from each step is crucial.

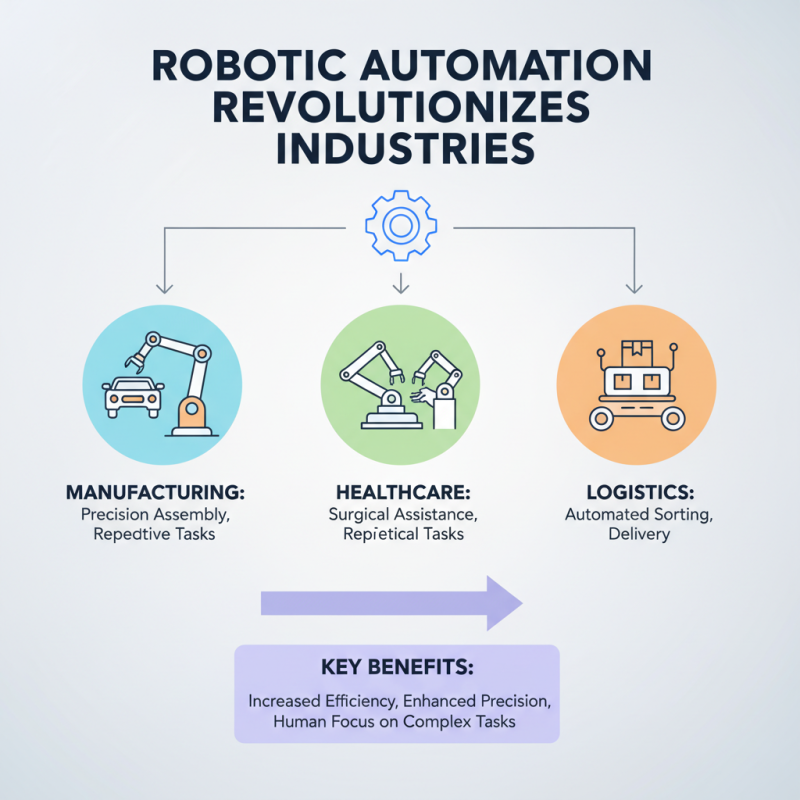

Robotic automation is revolutionizing how industries operate. It involves the use of robots to perform tasks previously done by humans. This technology spans various sectors, including manufacturing, healthcare, and logistics. In manufacturing, robotic arms assemble products with precision and speed. They handle repetitive tasks, which frees up human workers for more complex responsibilities.

In healthcare, robotic systems assist in surgeries and patient care. These robots reduce the margin for error and enhance efficiency. However, the transition to robotic automation is not without challenges. Workers may fear job loss, and industries must address this concern. Successful integration requires training and support for employees.

In logistics, automation streamlines inventory management and delivery systems. Robotics can sort and package goods faster than manual labor. Despite the benefits, companies must be cautious. Over-reliance on technology may lead to vulnerabilities. Balancing automation with human oversight is vital for sustained success in an automated landscape.

Robotic automation is reshaping industries across the globe. Key technologies are driving this transformation, offering both benefits and challenges. Machine learning algorithms enable robots to learn and adapt. This ability allows for high efficiency in repetitive tasks. However, relying heavily on these systems raises questions about job displacement. Workforce concerns need to be addressed as robots take on more roles.

Another significant technology is computer vision. It enables robots to perceive their surroundings. This advancement is crucial in fields like manufacturing and logistics. Robots can now sort, package, and manage inventory with precision. Yet, this reliance on automation might lead to over-dependence. Companies should balance automation with human oversight to ensure quality and safety.

Additionally, advancements in artificial intelligence contribute to automation. AI systems can analyze massive data sets to optimize processes. This capability boosts productivity and reduces operational costs. Despite the advantages, organizations must reflect on the ethical implications of AI. Ensuring that technology benefits all stakeholders is vital. While the future of robotic automation is bright, it calls for careful consideration and responsible implementation.

Robotic automation is reshaping industries around us.

In manufacturing, robots take on repetitive tasks. They assemble products with precision. This reduces human error and increases efficiency.

However, not all jobs can be automated. Skilled workers are still needed for complex tasks.

In healthcare, robotic systems assist in surgeries. These machines can perform delicate procedures.

They enhance surgeons' capabilities and improve recovery times. Yet, there are concerns about over-reliance on technology.

What happens if the system fails?

Robotic automation is changing industries rapidly, driven by its numerous benefits. One significant advantage is increased efficiency. According to a 2022 report from McKinsey, companies can boost productivity by up to 30% by incorporating robotic systems. This surge in efficiency helps businesses meet rising consumer demands effectively.

Another key benefit is cost reduction. Implementing robotic automation can lower operational costs by 20% on average. Tasks that once needed human intervention can be executed with precision and speed. However, it’s essential to remember that initial setup costs can be substantial. Not all businesses see immediate returns. Some struggle with technology adaptation. Industry reports indicate that approximately 30% of automation initiatives fail due to inadequate planning.

Additionally, automation enhances safety in various environments. Robots can perform dangerous tasks, reducing workplace accidents. For instance, sectors like manufacturing and logistics report fewer injuries post-automation. However, a reliance on technology raises concerns about job displacement. While automation creates new roles, it also challenges the workforce to upskill. This aspect needs continuous reflection and careful planning for a balanced transition.

Robotic automation is reshaping industries, yet challenges remain. Notably, a study by McKinsey reveals that automation could replace 30% of global work by 2030. This shift raises concerns about job displacement. Workers in manufacturing and retail may face the brunt. Training programs are essential but often insufficient.

Additionally, integration issues persist. Companies struggle to blend robots into existing systems. The cost of implementation can be high. According to Deloitte, nearly 53% of organizations cite cost as an obstacle. Furthermore, there are safety considerations. Ensuring a secure environment for human workers alongside robots is paramount. Companies must prioritize safety protocols.

Looking ahead, the landscape is promising but uncertain. A report from Gartner predicts that by 2025, 75% of organizations will employ some form of robotic process automation. As industries adopt these technologies, businesses must address ethical implications. Balancing efficiency and workforce welfare is crucial. The future of robotic automation depends on navigating these challenges carefully.

Taking Custom Design to New Levels

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

Fabricator

Inside Sales and Client Support Manager

Glass Handler – 1st Shift