Taking Custom Design to New Levels

PROUD TO BE PART OF THE BRIN FAMILY OF COMPANIES

OTHER BRIN LOCATIONS

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

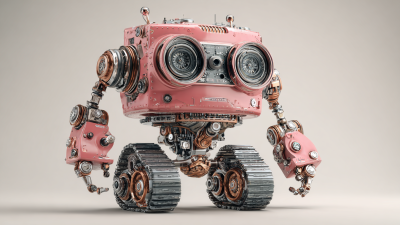

The field of robot design is rapidly evolving, driven by innovative approaches aimed at sustainability in various industries. According to a report by the International Federation of Robotics, the global market for robotics is projected to reach $210 billion by 2025, underscoring the urgent need for sustainable practices in the sector. As environmental concerns become increasingly paramount, engineers and designers are tasked with integrating eco-friendly materials and energy-efficient technologies into their creations. Recent advancements in artificial intelligence and machine learning also mean that robots can adapt and optimize their operations to minimize waste and energy consumption. By adopting innovative strategies in robot design, we can create solutions that not only enhance productivity but also promote environmental stewardship, thus paving the way for a more sustainable future. This article delves into the transformative approaches that are shaping the future of robot design and their implications for various sectors.

The exploration of innovative materials is pivotal in the realm of sustainable robot design. Advancements in bioplastics, recycled metals, and smart materials are transforming the way robots are constructed, significantly reducing their environmental impact. For instance, bioplastics derived from organic sources offer a biodegradable alternative to traditional plastics, minimizing waste and pollution. Additionally, the use of recycled metals not only conserves natural resources but also decreases energy expenditure in production processes. These materials not only enhance sustainability but also contribute to the durability and functionality of robots.

Moreover, innovative materials such as programmable matter and shape-memory alloys are reshaping robot capabilities, allowing for designs that are adaptable and responsive to their environments. These materials can change form to optimize energy efficiency and operational effectiveness during tasks such as waste management or environmental monitoring. The incorporation of these smart materials holds the potential to create robots that not only perform effectively but also align with sustainability goals, facilitating a more eco-friendly approach to future robotics design. By focusing on these innovations, the robotics industry can significantly contribute to a more sustainable future.

The integration of artificial intelligence (AI) and machine learning in robot design is shaping a promising future for sustainable solutions across various industries. By 2025, the global artificial intelligence robots market is projected to reach $6.19 billion, with aspirations to soar to $32.26 billion in the following years. This tremendous growth underscores the increasing reliance on smart robots, particularly in manufacturing environments where efficiency is paramount. AI-driven robots are enhancing production processes by optimizing speed, improving quality, and minimizing costs, thus transforming traditional manufacturing landscapes.

Furthermore, the application of AI extends beyond manufacturing to supply chain management, marking a critical evolution from Industry 4.0 to Industry 6.0. A systematic literature review highlights how AI optimizes every stage of the supply chain, driving efficiency and responsiveness. As businesses increasingly adopt advanced automation strategies, such as those seen in next-generation warehouses, the synergy between AI and robotics fosters unparalleled levels of operational efficiency and innovation. By leveraging these technologies, companies are not only enhancing their productivity but also paving the way for a more sustainable future in robotics design.

As we venture into an era where sustainability is paramount, the design of modular robots emerges as a critical innovation. Modular robots consist of interchangeable components that can be easily reconfigured or replaced, addressing the growing need for vehicles that can adapt to various tasks while minimizing waste. This design philosophy not only extends the lifespan of the robots but also allows for greater flexibility in their functionality. When a particular module becomes obsolete or requires upgrading, users can simply replace it instead of discarding the entire system, thus promoting a more sustainable approach to robotics.

Moreover, the ease of upgrading and repairing modular robots aligns with the principles of circular economy. By facilitating quick and cost-effective repairs, these robots can remain in service longer, reducing the environmental impact associated with manufacturing new units. Each module can be designed with user-friendly interfaces, enabling technicians and enthusiasts alike to engage in modifications without extensive technical training. This democratization of technology empowers a wider community to contribute to the evolution of robotic systems, driving innovation while championing sustainability.

| Robot Type | Primary Function | Modularity Level | Upgradability (Years) | Repairability |

|---|---|---|---|---|

| Agricultural Robot | Crop Monitoring | High | 5 | Easy |

| Delivery Robot | Package Delivery | Medium | 4 | Moderate |

| Construction Robot | Brick Layering | High | 6 | Difficult |

| Healthcare Robot | Patient Assistance | Medium | 3 | Easy |

| Educational Robot | Learning & Teaching | High | 5 | Moderate |

Sustainable energy sources are paramount in the development of next-generation robotics, as they seek to enhance functionality while minimizing environmental impact. According to a report by MarketsandMarkets, the global robotics market is projected to reach USD 214 billion by 2025, with a significant emphasis on integrating green technology. As robotic applications diversify across industries such as agriculture, manufacturing, and healthcare, the need for energy-efficient solutions becomes increasingly critical.

One innovative approach to sustainable energy in robotics is the use of bio-inspired energy systems. Research from the IEEE Transactions on Robotics indicates that robots mimicking natural processes can harness renewable energy more effectively, utilizing mechanisms such as solar panels or piezoelectric materials. For example, energy-harvesting robots can generate power dynamically while performing tasks, bolstering their operational efficiency and autonomy. This shift not only reduces reliance on conventional power sources but also aligns with global sustainability goals, fostering a greener future for robotic technology. As we continue to push the boundaries of what robots can achieve, sustainable energy solutions will play a central role in their design and application.

As robotics continues to evolve, the importance of user-centric design in robot development cannot be overstated. Engaging communities in the design process ensures that these technologies address real-world needs and challenges. By involving users from diverse backgrounds, developers can gain valuable insights into how robots can enhance daily life, promote sustainability, and foster social interactions. This collaborative approach not only helps refine robotic solutions but also cultivates a sense of ownership among users.

Moreover, the recent entrepreneurial showcase highlighted innovative projects that focus on integrating user feedback into robotic design. Startups presented ideas ranging from intelligent infrastructure to embodied AI, all aimed at creating more accessible and beneficial robotic applications. This emphasis on community engagement signals a shift towards designing robots that not only serve functional purposes but also resonate emotionally with users, paving the way for more sustainable and accepted technological solutions in the future.

Taking Custom Design to New Levels

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

Fabricator

Inside Sales and Client Support Manager

Glass Handler – 1st Shift