Taking Custom Design to New Levels

PROUD TO BE PART OF THE BRIN FAMILY OF COMPANIES

OTHER BRIN LOCATIONS

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

The landscape of manufacturing is undergoing a transformative shift with the increasing integration of collaborative robot arms. According to the World Economic Forum's "The Future of Jobs Report 2020," by 2025, automation technologies, including collaborative robots, are expected to significantly impact the workforce, potentially displacing 85 million jobs while creating 97 million new roles that focus on the human-robot collaboration. This changing dynamic highlights the pivotal role of collaborative robot arms in enhancing productivity, efficiency, and safety across various manufacturing sectors.

As industries strive to optimize operations and meet the demands of an evolving market, collaborative robot arms have emerged as a vital solution. A report by MarketsandMarkets predicts that the global market for collaborative robots will reach $12.3 billion by 2025, growing at a compound annual growth rate (CAGR) of 34.5% from 2020. This rapid growth underscores the increasing acceptance and application of robotic automation, not just as a replacement for human labor, but as a partner that augments human capabilities in a safe operational environment.

In this exploration of the future of manufacturing, we will delve into how collaborative robot arms are not only redefining automation but also reshaping workforce dynamics, enhancing safety protocols, and driving innovation in production processes. Understanding the potential and challenges associated with this technology is essential for businesses aiming to remain competitive in an ever-evolving industrial landscape.

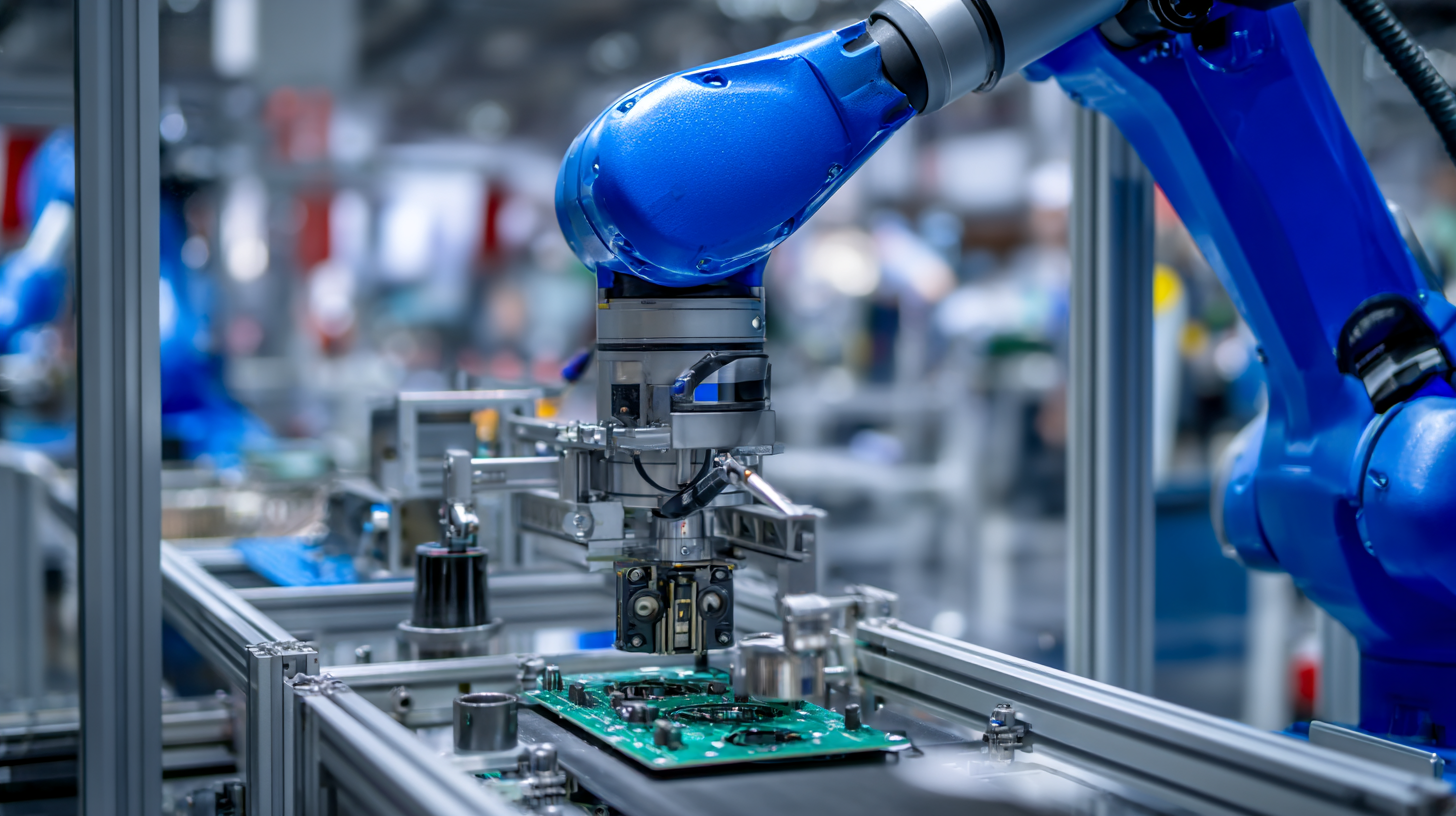

The manufacturing landscape is undergoing a significant transformation with the increasing integration of collaborative robot arms, commonly known as cobots. Unlike traditional industrial robots designed to work in isolation, cobots are engineered to work alongside human workers, enhancing productivity while ensuring safety. Their intuitive programming and adaptability allow them to take on a variety of tasks, from assembly line work to quality inspection. This collaborative approach not only streamlines manufacturing processes but also enables workers to focus on more complex and creative tasks that require human ingenuity.

As industry demands evolve, the rise of collaborative robot arms in modern manufacturing is fueled by their versatility and cost-effectiveness. Companies can deploy these robots in small batches, making automation accessible to small and medium-sized enterprises that previously could not afford such technology. Additionally, the ability of cobots to easily adapt to different workflows means that they can be retrained or repurposed as production needs change. This flexibility positions collaborative robots as essential tools for future-proofing manufacturing operations, providing a competitive edge in a rapidly changing marketplace.

The integration of collaborative robots, or cobots, into manufacturing production lines offers a multitude of benefits that can transform traditional automated processes. One of the most significant advantages is enhanced safety in the workplace. Unlike traditional industrial robots that operate in isolation and require safety barriers, cobots are designed to work alongside human operators. Equipped with advanced sensors and real-time processing capabilities, these robots can detect human presence and adjust their movements accordingly, minimizing the risk of accidents and promoting a safer working environment.

Another key benefit of incorporating collaborative robots is the flexibility they bring to manufacturing. Cobots are typically lightweight and easy to program, allowing for quick reconfiguration of production lines to meet changing demands. This adaptability means manufacturers can respond swiftly to market changes, such as varied product designs or fluctuating order volumes, without the need for extensive downtime or costly retooling. Additionally, by automating repetitive tasks, cobots free up human workers to focus on more complex and value-added activities, ultimately leading to increased productivity and job satisfaction.

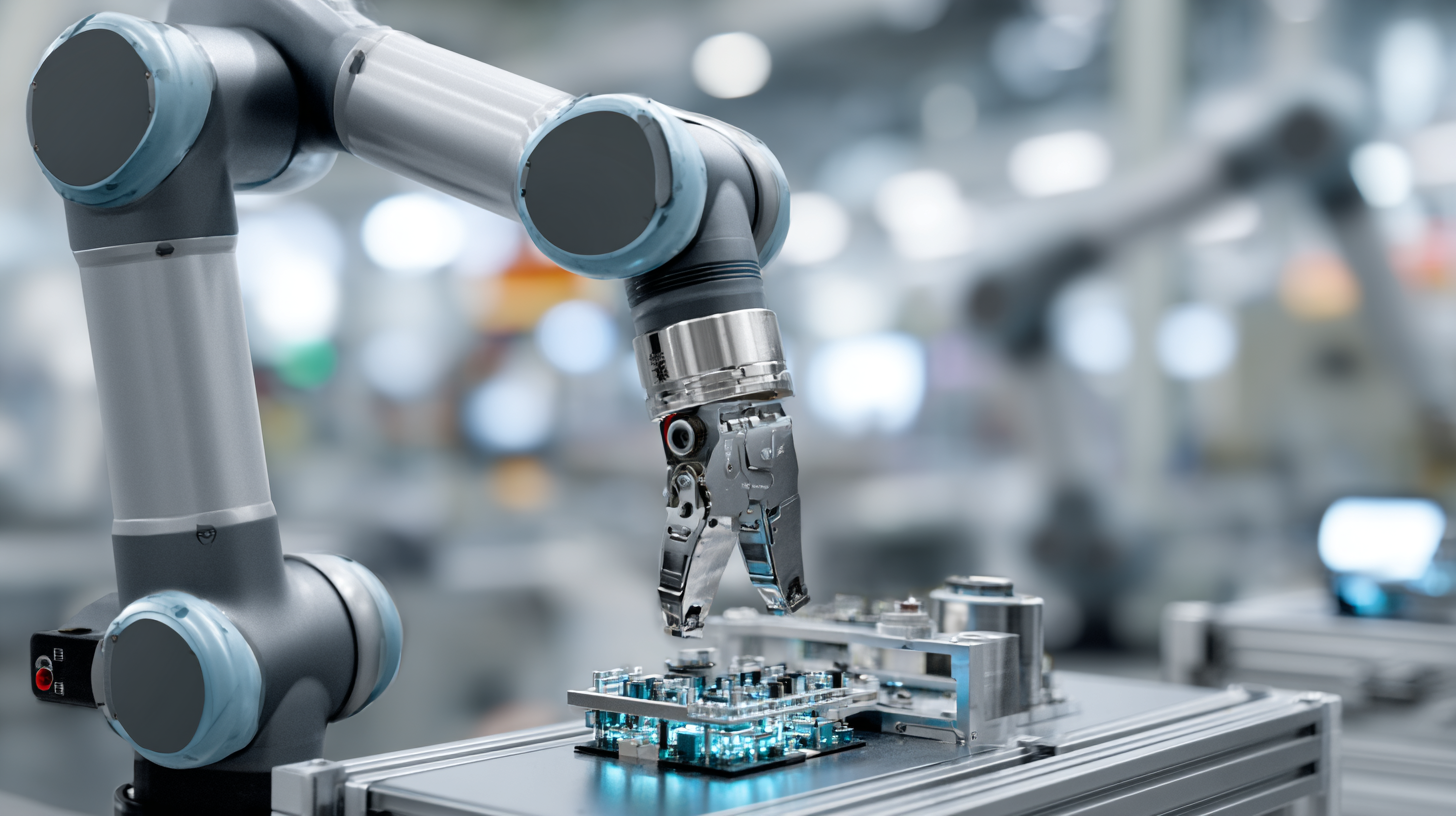

Collaborative robots, or cobots, are revolutionizing the manufacturing landscape by seamlessly integrating with human workers. These advanced robotic arms are designed to operate alongside their human counterparts, enhancing productivity without replacing the invaluable human touch. Unlike traditional industrial robots that are often isolated within safety cages, cobots can work in close proximity to people, learning from their movements and adapting to real-time conditions. This synergy not only boosts efficiency but also promotes a safer working environment, where operators can focus on higher-level tasks while leaving repetitive or dangerous duties to the robots.

The enhancement of human-machine collaboration is at the heart of the cobot revolution. These robots are equipped with sophisticated sensors and AI capabilities, allowing them to analyze the actions of human operators and respond appropriately. By assisting with tasks such as assembly, quality control, and material handling, cobots empower workers to achieve their full potential. Furthermore, their user-friendly interfaces enable easy programming and adaptation, making them accessible even to those with limited technical expertise. As industries embrace this collaborative approach, the potential for innovation and productivity in manufacturing continues to grow, setting the stage for a more agile and responsive production environment.

The rise of collaborative robot arms in manufacturing presents exciting opportunities, yet it also comes with several challenges and limitations. One significant hurdle is the integration of these robotic systems into existing workflows and technologies. Manufacturers often face compatibility issues between collaborative robots and current equipment, which can lead to increased transition times and unexpected costs. Additionally, ensuring that the robot arms can work safely alongside human workers requires comprehensive training and adherence to stringent safety protocols.

Tips: To ease the integration process, consider starting with a pilot project that incorporates collaborative robots into a specific task. This approach allows for adjustments and improvements without overwhelming the entire production line. Moreover, investing in training programs for your workforce can enhance safety and efficiency when introducing new robotic technologies.

Another challenge lies in the programming and adaptability of collaborative robot arms. While many models are designed for ease of use, programming for specific tasks can still be complex and time-consuming. Manufacturers may encounter difficulties in customizing the robots to meet their unique production needs, resulting in operational delays.

Tips: Regularly updating training materials and resources can help your team stay informed about the latest robot programming advancements. Additionally, collaborating with robot manufacturers for specialized training sessions can facilitate smoother operations and empower your staff to maximize the potential of these automated systems.

The landscape of manufacturing is undergoing a significant transformation with the advent of collaborative robotics. Innovations in this field are driving new capabilities in automation, allowing robots to work alongside humans safely and efficiently. One of the most notable trends is the development of advanced sensory technologies that enable robot arms to perceive their environments better, recognizing human presence and adjusting their actions accordingly. This enhancement not only improves operational safety but also facilitates more complex tasks that require a high degree of precision.

Another exciting trend is the integration of artificial intelligence in collaborative robotics. AI algorithms allow robots to learn from their interactions, becoming more adaptable and intelligent over time. This capability enables them to optimize production processes, reduce downtime, and enhance overall productivity. Additionally, the use of user-friendly programming interfaces is democratizing access to robotic automation, allowing smaller manufacturers to implement sophisticated solutions without needing extensive technical expertise. As these technologies continue to evolve, we can expect a future where collaborative robot arms play an even more integral role in manufacturing ecosystems, driving innovation and efficiency across various sectors.

Taking Custom Design to New Levels

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

Fabricator

Inside Sales and Client Support Manager

Glass Handler – 1st Shift