Taking Custom Design to New Levels

PROUD TO BE PART OF THE BRIN FAMILY OF COMPANIES

OTHER BRIN LOCATIONS

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

In recent years, the field of robotic arms has seen immense progress, captivating industries and enthusiasts alike. As Dr. Sarah Thompson, a leading expert in robotics, once said, "Robotic arms are transforming the way we think about automation and human collaboration." This statement reflects the evolving landscape where these innovations are not just tools but integral partners in various sectors.

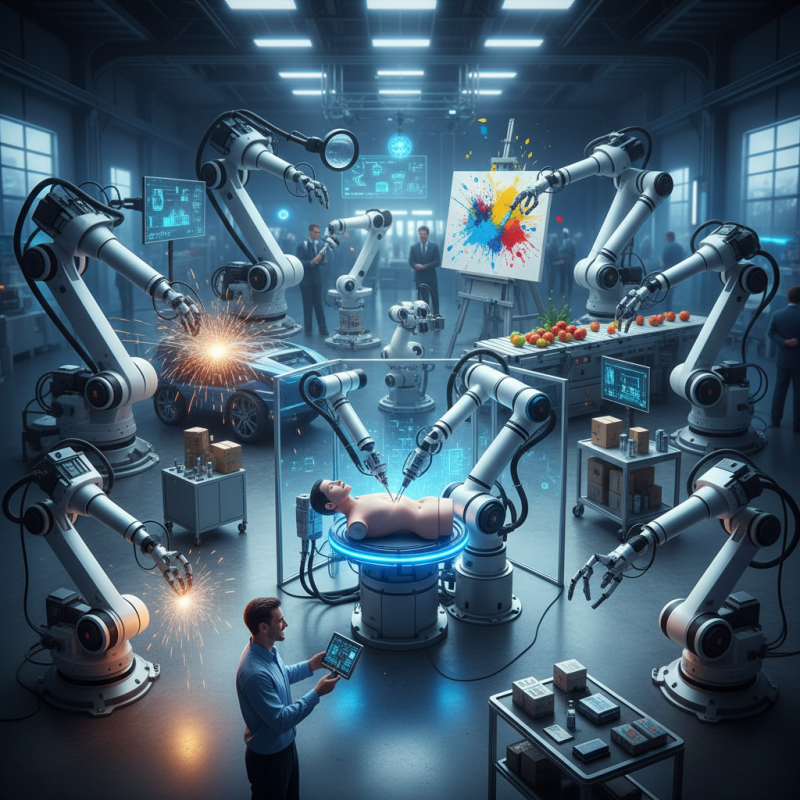

Innovations in robotic arms have permeated manufacturing, healthcare, and even art, demonstrating their versatility. From precise surgical robots to artistic robotic arms that paint, the applications are endless. These machines can work tirelessly, surpassing human limitations in both speed and accuracy. Yet, despite their capabilities, concerns remain about reliance on technology and the potential loss of human skills.

As the human-robot relationship grows, we must acknowledge the complexities it introduces. The balance between efficiency and creativity is delicate. Some argue that over-automation risks diminishing human touch in various fields. Reflecting on these challenges is crucial as we embrace the future of robotic arms. The innovations are fascinating, yet they call for a deeper understanding of their implications in our daily lives.

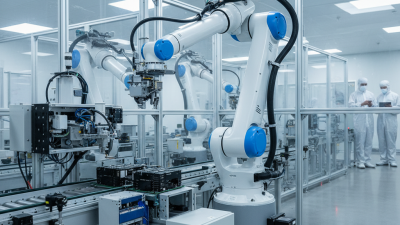

The manufacturing industry is undergoing a significant transformation. Innovative robotic arm technologies are at the forefront. These advanced systems enhance efficiency and precision on factory floors. They work alongside human operators, creating a collaborative environment. This partnership allows for higher productivity and better safety measures in various applications.

Recent developments in robotic arms include advanced sensors and AI integration. These features improve real-time decision-making. Robotic arms can now adapt to changing tasks quickly. Their ability to learn from experience makes them even more valuable.

However, these innovations are not without challenges. Adapting existing workflows to accommodate new technologies can be complex. Moreover, the initial investment in robotic arms can be daunting. Smaller manufacturers may struggle to keep up. It's vital to consider the long-term benefits and potential return on investment.

As technology continues to evolve, the robotics landscape will likely shift further. This evolution calls for continuous reflection on best practices and adjustments in strategies. Balancing human intuition with robotic precision remains a critical task for the future.

Robotic arm innovations are transforming medical applications. Precision is essential in surgeries. According to a recent industry report, robotic-assisted procedures have increased by 20% yearly. These advanced systems allow for minimal invasiveness, reducing recovery times.

Surgeons can use robotic arms for delicate tasks. Enhanced dexterity and accuracy lead to better outcomes. For instance, robotic arms can perform suturing with a precision of 0.5 mm. This level of accuracy can be life-changing for patients. However, challenges remain. Integration with existing practices can be complex and may require training.

**Tips:** Be aware that not all robotic systems are the same. Understanding their capabilities is crucial. Evaluate how they fit into your medical practice. Continuous improvement is vital as technology evolves. Regularly assess performance and patient outcomes. Data indicates that maintaining high standards in surgery correlates with robotic arm utilization.

Medical professionals should engage with these innovations cautiously. While the benefits are clear, the learning curve is steep. Embracing new technology can be daunting. Balancing efficiency and patient care should remain a priority.

| Innovation | Precision Level | Medical Application | Year of Introduction |

|---|---|---|---|

| Robotic Surgical Assistant | 0.1 mm | Minimally Invasive Surgery | 2015 |

| Dynamic Motion Tracking Arm | 0.05 mm | Orthopedic Surgery | 2020 |

| Teleoperated Robotic Arm | 0.2 mm | Remote Surgery | 2019 |

| AI-Enabled Surgical Arm | 0.1 mm | Cardiac Procedures | 2022 |

| Soft Robotic Arm | 0.3 mm | Rehabilitation | 2021 |

| Haptic Feedback Arm | 0.2 mm | Surgery Training | 2020 |

| Automated Tissue Stitching Arm | 0.1 mm | Wound Closure | 2023 |

| Miniaturized Robotic Arm | 0.05 mm | Brain Surgery | 2024 |

| Robotic Arm with Image Recognition | 0.1 mm | Tumor Removal | 2021 |

| Next-Gen Robotic Arm | 0.07 mm | General Surgery | 2025 |

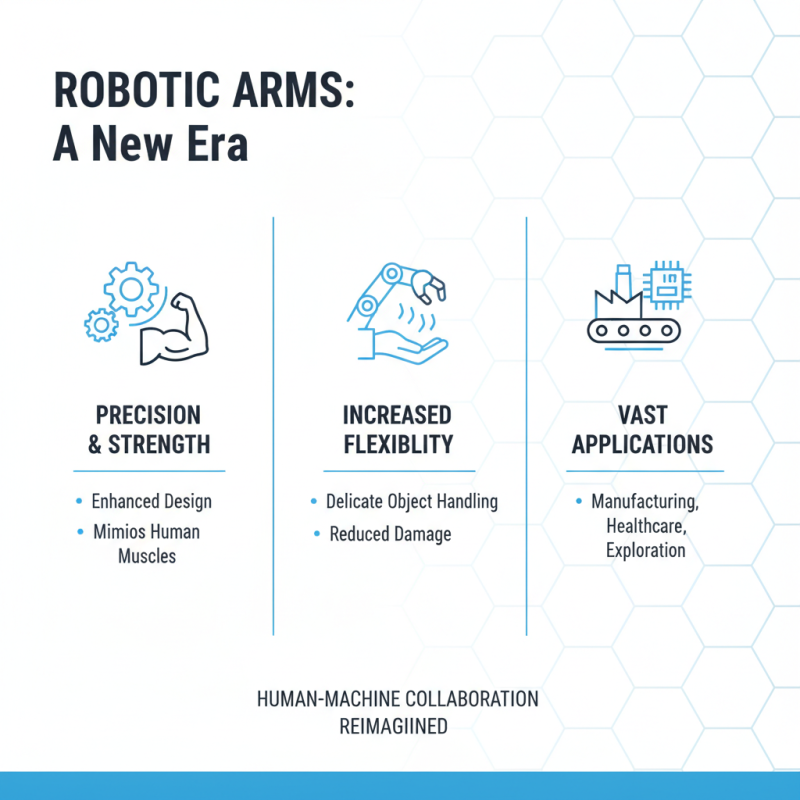

Robotic arms have made remarkable strides. They are changing how humans and machines work together. Advances in design enhance precision and strength. For example, some robotic arms now mimic human muscles. This allows for greater flexibility in tasks. They can handle delicate objects without damage. The potential applications are vast.

However, there are challenges that need reflection. While these robotic arms improve efficiency, they also raise questions. Are we relying too much on machines? The balance between human input and automation is crucial. Some robotic arms still struggle with complex tasks. They may not always understand contextual cues. This can lead to errors in production lines. It is vital to address these gaps for better collaboration.

Further innovations are on the horizon. Researchers are exploring more intuitive control systems. These systems may allow unsophisticated users to operate robotic arms effortlessly. Learning from failures is essential. By analyzing shortcomings, we can develop superior designs. The journey of enhancing human-machine collaboration continues. It involves a mix of excitement and reflection.

Agriculture is witnessing a revolutionary change with the rise of autonomous robotic arms. These innovations are designed to enhance efficiency and sustainability in farming practices.

According to recent studies, the integration of robotic technology can increase crop yield by as much as 30%. This statistic highlights the potential of robotics to transform traditional farming methods.

Robotic arms handle various tasks like planting, harvesting, and even sorting produce. They operate with precision and can work long hours without fatigue. Farmers are increasingly adopting these technologies, driven by rising labor costs and a decreasing workforce in rural areas. For instance, a report indicated that over 20% of agriculture jobs remain unfilled. This gap makes robotic solutions increasingly appealing.

Tip: Consider investing in training for staff to work alongside robotic systems. Collaboration between humans and machines can optimize workflow, ensuring that both provide maximum benefit.

However, not all implementations are flawless. Some farmers report high initial setup costs and technical issues. Maintenance can also be challenging. It’s essential to weigh the pros and cons before making a leap into robotic integration. Balancing investment and efficiency is key to success in this evolving agricultural landscape.

Tip: Start small with automation projects. Testing robotic arms on limited plots can help gauge effectiveness and make adjustments as needed.

The future of robotic arm innovations holds immense promise for various sectors. Reports indicate that the global robotic arm market could reach $30 billion by 2027, driven by advancements in artificial intelligence and machine learning. As industries grow more automated, the integration of robotic arms is crucial. They enhance precision in manufacturing, packaging, and even surgery. Yet, the speed of this change raises concerns.

Ethical implications are also surfacing. As machines handle intricate tasks, job displacement is a real fear. A recent study suggests that up to 20% of jobs could be automated within the next decade. How society adapts remains uncertain. Will we embrace the change, or resist it? We must critically assess the balance between innovation and employment.

Furthermore, the impact on health care is significant. Robotic arms are redefining surgery by improving accuracy and outcomes. But they also highlight disparities. Access to these technologies may not be equal. As we innovate, we must consider social equity. Each advancement should invite reflection on how it affects humanity as a whole.

Taking Custom Design to New Levels

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

Fabricator

Inside Sales and Client Support Manager

Glass Handler – 1st Shift