Taking Custom Design to New Levels

PROUD TO BE PART OF THE BRIN FAMILY OF COMPANIES

OTHER BRIN LOCATIONS

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

In the rapidly evolving field of robot design, creating efficient, functional, and innovative robots has become paramount for enhancing various projects across industries. As technology advances, the need for thoughtful and meticulous design strategies has never been more critical. Renowned robot design expert Dr. Elena Rodriguez states, "A well-designed robot not only performs tasks but also integrates seamlessly into the environment while adapting to user needs." This highlights the importance of user-centric approaches in robot design, which can significantly influence the success of any robotic application.

Effective robot design involves several key considerations, from selecting appropriate materials to optimizing functionality and ensuring user-friendliness. Designers must navigate a complex landscape of engineering principles, aesthetics, and human interaction to craft robots that meet both technical specifications and user expectations. The following tips will delve into essential strategies and insights that can elevate your projects, showcasing the intricate balance between creativity and functionality that defines successful robot design. With these guidelines in hand, innovators can look forward to developing robots that not only fulfill their intended purposes but also push the boundaries of what is possible in automation and robotics.

Effective robot design is fundamental to the success of any robotics project. One key principle to consider is modularity. According to a report by the International Federation of Robotics, modular designs can significantly reduce development time and costs by 30-50%. Modularity allows different components to be developed and tested independently, facilitating quicker iterations and easier upgrades, which is vital in the fast-paced robotics landscape. When designing robots, engineers should focus on creating interchangeable parts that can easily be updated or replaced as technology advances.

Another principle that enhances project success is prioritizing usability. The Human Factors and Ergonomics Society highlights that ensuring robots are user-friendly can improve user satisfaction and operational efficiency. Implementing intuitive user interfaces and accessible controls can decrease training time by as much as 25%, enabling teams to focus on innovative applications rather than mastering complex systems. Furthermore, conducting user testing during the design phase can provide valuable insights, helping engineers to refine designs to better meet user needs, ultimately leading to more successful deployments across various applications.

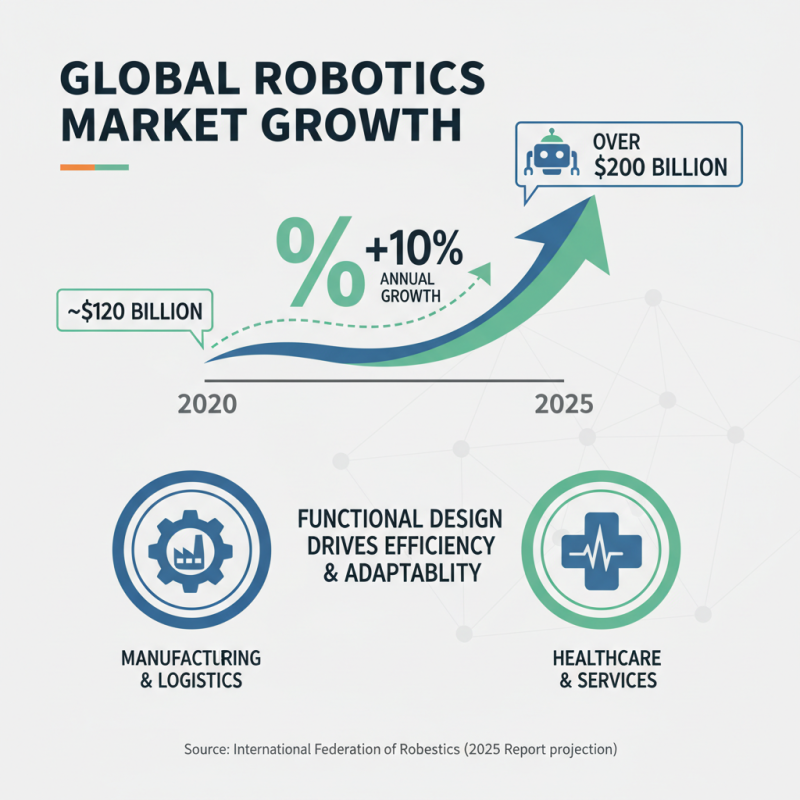

In the realm of robotics, the functionality of a design is paramount. According to a recent report by the International Federation of Robotics, the global robot market is expected to grow by 10% annually, reaching over $200 billion by 2025. This surge underscores the crucial role that effective robot design plays in meeting operational needs across various sectors, from manufacturing to healthcare. By prioritizing functionality, designers can create robots that not only perform tasks efficiently but also adapt to the dynamic environments they operate in.

One essential tip for enhancing a robot's functionality is to integrate user feedback during the design process. Engaging potential end-users can provide invaluable insights into practical requirements and usability challenges that might not be immediately apparent to designers. Additionally, leveraging simulation tools during the design phase can help visualize potential operational circumstances and refine functionality before physical prototypes are developed.

Another crucial aspect is ensuring that the robot’s components are easily upgradable. Research indicates that 65% of robotics project failures stem from inadequate adaptability to evolving technologies. Designing for modularity allows for easy replacement or upgrading of parts, which can significantly extend a robot's lifespan and performance capabilities. By focusing on these principles, designers can create robots that not only fulfill current requirements but also remain relevant in a rapidly advancing technological landscape.

Designing robots with user-centric features is essential for enhancing usability and ensuring successful integration into various environments. According to a report by the International Federation of Robotics, the increasing adoption of collaborative robots, or cobots, highlights the importance of designing machines that prioritize user experience. These robots are revolutionizing workplaces by making complex tasks simpler and safer for human operators. By focusing on user-centric design, engineers can ensure that their robots are not only functional but also intuitive, reducing the learning curve for new users.

When incorporating user-centric features, it is crucial to consider accessibility and adaptability. A study published in the Journal of Human-Robot Interaction indicates that 75% of users prefer robots that can be easily customized to meet individual needs. This adaptability fosters a more engaging interaction between humans and robots, creating an environment where users feel more in control. Features such as intuitive interfaces, clear feedback systems, and customizable settings can significantly enhance the usability of robotic systems, making them more appealing and effective in real-world scenarios. As the robotics industry continues to evolve, prioritizing user-centric design practices will be instrumental in developing technologies that genuinely meet the needs of their operators.

When it comes to effective robot design, utilizing robust materials and technology is crucial for ensuring longevity and performance. According to a report by the International Federation of Robotics, robots built with advanced materials exhibit a significant reduction in wear and tear, extending their lifecycle by up to 30% compared to those constructed from traditional materials. This is particularly important in industries where robots are subjected to harsh conditions, such as manufacturing and logistics, where even minor failures can result in costly downtimes.

Incorporating technologies like advanced polymers and alloy composites can greatly enhance the resilience of robotic components. A study published in the Journal of Robotics and Automation Research highlights that the application of high-strength materials not only improves physical durability but also contributes to a robot’s overall energy efficiency. For example, lighter materials can reduce the operational load on motors, enhancing performance and optimizing energy consumption.

As these innovations continue to evolve, the integration of smart materials that can respond to environmental changes is likely to offer new opportunities for creating robots that are not only durable but also adaptable to a wider range of applications.

Testing is a crucial phase in the development of robotics projects that can significantly influence the overall reliability and functionality of the final product. By systematically testing each component and system integration, engineers can identify issues before they become costly problems. This involves not only evaluating the physical aspects of the robot, such as movement and dexterity but also assessing the code and algorithms that drive its behavior. Establishing a robust testing protocol that includes unit tests, integration tests, and system tests ensures that every part of the robot performs as expected under varying conditions.

Iteration is equally essential, as it fosters continuous improvement. After testing, the insights gained should guide the redesign and optimization of both the hardware and software components. Changes made during the iteration phase are crucial for refining the robots’ performance and reliability. By creating prototypes and using feedback from testing, developers can pinpoint weaknesses and enhance the design progressively. This cycle of testing and iteration creates a feedback loop that ultimately leads to a more reliable and effective robotic system, empowering creators to push the boundaries of what their projects can achieve.

| Tip Number | Tip | Description | Importance Level |

|---|---|---|---|

| 1 | Define Clear Objectives | Establish precise goals for your robot's functionality. | High |

| 2 | Iterative Design Process | Use a cyclic development approach to improve designs. | Moderate |

| 3 | Prototype Early and Often | Create prototypes to test concepts rapidly. | High |

| 4 | Focus on Modularity | Design components that can be easily replaced or upgraded. | High |

| 5 | Test in Real Environments | Validate performance under actual operating conditions. | Very High |

| 6 | User Feedback | Incorporate user experiences to enhance design quality. | Moderate |

| 7 | Prioritize Reliability | Ensure components can withstand operational stresses. | Very High |

| 8 | Use Robust Materials | Select materials that enhance durability and efficiency. | High |

| 9 | Document Changes | Keep track of design modifications for reference. | Moderate |

| 10 | Conduct Regular Reviews | Frequent evaluations help identify issues early. | High |

Taking Custom Design to New Levels

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

Fabricator

Inside Sales and Client Support Manager

Glass Handler – 1st Shift