Taking Custom Design to New Levels

PROUD TO BE PART OF THE BRIN FAMILY OF COMPANIES

OTHER BRIN LOCATIONS

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

In recent years, the use of manufacturing robots has surged dramatically. According to the International Federation of Robotics, the global market for industrial robots is expected to reach $70 billion by 2028. This growth reflects how crucial automation is for businesses striving for efficiency and innovation. Choosing the right manufacturing robots is vital for your operations, as it can significantly impact productivity and profitability.

Many companies face challenges when selecting manufacturing robots that meet their specific needs. Factors such as the type of tasks, workspace layout, and budget constraints must be considered. A report by PwC indicates that 45% of jobs could be automated, putting pressure on businesses to invest wisely in automation technology. However, not all robots are created equal, and making an uninformed decision can lead to inefficient processes and wasted resources.

In this landscape, it's essential to approach the selection of manufacturing robots with careful analysis. Strategies should be based on solid data rather than trends to mitigate risks. The effectiveness of the deployed robots depends on adaptability to various tasks and environments. As businesses adopt these technologies, evaluating performance and making adjustments is necessary to ensure long-term success.

Choosing the right manufacturing robots involves considering several key factors. The production environment plays a vital role. A clean space might require different robots compared to a factory with heavy pollution. According to a recent industry report, nearly 40% of robot failures are due to environmental mismatches. It's critical to assess your unique setting carefully.

Another important factor is the type of tasks the robots will perform. Some robots excel in repetitive tasks, while others are designed for flexibility. A study from the International Federation of Robotics indicates that 70% of manufacturers reported increased efficiency after aligning robot capabilities with tasks. Many businesses overlook this alignment, leading to suboptimal performance.

Cost is a significant factor. Initial investment can be high, and cheaper robots often compromise on quality. A survey revealed that 55% of companies experience hidden costs after choosing low-cost options. This means businesses must conduct thorough budgeting. Involvement of cross-functional teams can help identify potential pitfalls in the selection process.

The landscape of manufacturing robotics is evolving rapidly. Businesses now face new demands. Automation is not just a trend; it's a necessity for survival. Companies are looking for robots that enhance efficiency and adaptability. Lines between tasks are blurred, as robots are capable of taking on diverse roles. In this shifting environment, flexibility is key.

Industry trends indicate a push towards collaborative robots, or cobots. These machines work side by side with humans. They offer a safer and more dynamic approach to automation. However, integration can be challenging. Workers may need training to adapt to this technology. The initial investment can seem daunting. Yet, the long-term benefits often outweigh these upfront costs.

As companies consider their options, they must reflect on their specific needs. Not every robot fits every use case. Some tasks may be too complex for simple solutions. The right choice involves careful analysis and understanding. Companies must weigh potential returns against their operational goals. Each decision shapes the future of their manufacturing processes.

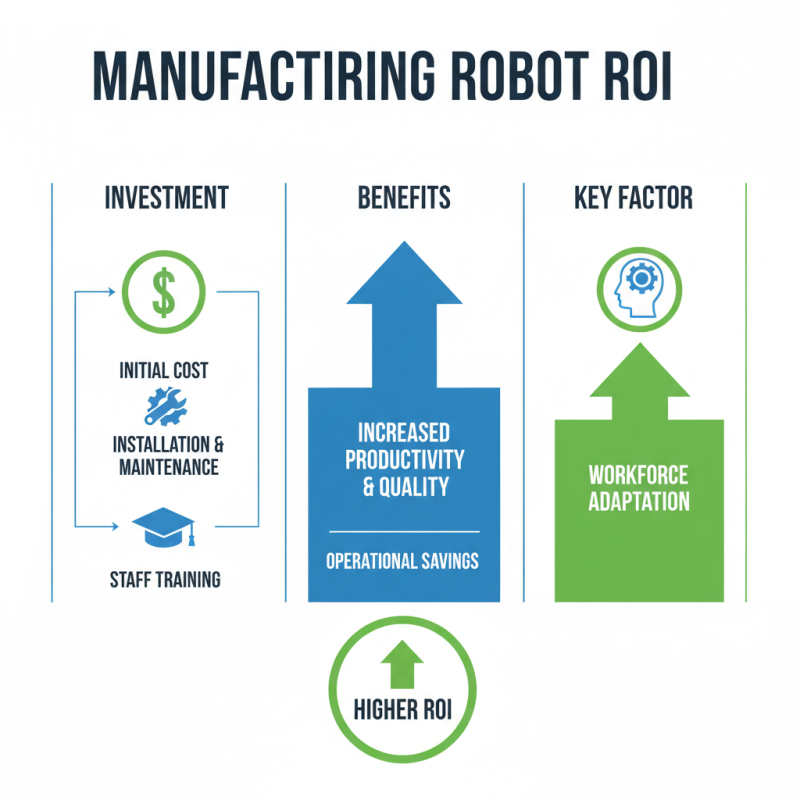

When evaluating the return on investment (ROI) for manufacturing robots, businesses should consider several key factors. The initial cost of the robots is crucial, but it's not the only expense. Installation and maintenance can add significantly to the total investment. Training staff to operate and maintain robots also requires consideration. The ROI will increase if the workforce can adapt quickly and efficiently.

An essential metric is productivity. Robots can work faster and longer than humans. This increased output can lead to cost savings. However, it’s important to track downtime. Breakdowns can reduce ROI dramatically. If a robot is out of service, the costs can escalate quickly. Some businesses underestimate these potential risks.

Another factor is adaptability. Some robots excel in specific tasks but struggle with others. Their flexibility can determine how quickly a company recovers its investment. Assessing the types of tasks they will perform helps calculate potential savings. A robot that can't meet future needs may require replacement sooner than expected, affecting overall ROI. It's a delicate balance that needs careful assessment.

Choosing the right manufacturing robots requires careful consideration of key technical specifications. One critical specification is payload capacity. For example, data suggests that a robot with a minimum payload of 10 kg is suitable for many assembly tasks. This capacity ensures that the robot can handle common manufacturing materials efficiently.

Another important factor is reach. Robots vary in reach, impacting their ability to access different areas of a workspace. Reports indicate that a reach of at least 1.2 meters is often necessary for assembly lines. This allows robots to work without hindrance and reduces downtime.

Additionally, speed and precision are vital. Robots that operate with a speed of 1 meter per second can significantly improve productivity. However, the trade-off between speed and accuracy must be assessed. Sometimes faster isn’t always better if it leads to errors.

Companies may overlook the importance of software compatibility. A robot that doesn't integrate well with existing systems can lead to inefficiencies. This oversight can hinder operations and add costs. Adapting to new technologies is not always seamless. Therefore, planning for integration is crucial to ensuring a smooth transition.

| Specification | Description |

|---|---|

| Payload Capacity | The maximum weight the robot can handle, typically measured in kilograms (kg). |

| Reach | The maximum distance the robot arm can extend, typically in millimeters (mm). |

| Degrees of Freedom | The number of axes the robot can move, influencing its flexibility and range of motion. |

| Speed | The maximum speed at which the robot can operate, typically measured in meters per second (m/s). |

| Repeatability | The precision with which the robot can return to a specific position, often measured in millimeters (mm). |

| Control Method | The system used to control the robot, such as teach pendant, offline programming, or software integration. |

| Safety Features | Built-in safety mechanisms to protect operators, such as emergency stop buttons and safety sensors. |

| Integration Compatibility | The ability to integrate with existing systems and equipment, ensuring seamless operation. |

| Maintenance Requirements | The frequency and type of maintenance needed to keep the robot functioning efficiently. |

Choosing the right manufacturing robots requires careful thought. Scalability and adaptability are key factors for future-proofing your business. You want robots that grow with your needs. This means looking for flexible systems that can handle different tasks.

Tips: Evaluate how easily the robots can be reprogrammed. Can they switch between tasks quickly? This flexibility adds value to your investment. Also, consider the training time for your staff. A user-friendly interface can save time and costs.

Your business needs may change. Look for robots that can integrate with new technology. This adaptability will keep your operations modern. Keep an eye on trends in automation. They can guide your decisions and reveal potential gaps in your current setup.

Tips: Think about future expansions. Will your robots be able to keep up? You may need to reassess regularly. Consider both your immediate needs and long-term goals. Sometimes, the most advanced robot isn't the best choice for your unique situation.

Taking Custom Design to New Levels

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

Fabricator

Inside Sales and Client Support Manager

Glass Handler – 1st Shift