Taking Custom Design to New Levels

PROUD TO BE PART OF THE BRIN FAMILY OF COMPANIES

OTHER BRIN LOCATIONS

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

In today's rapidly advancing technological landscape, the integration of automation into various industries has become a driving force for efficiency and productivity. Among the pivotal components of automation systems, the six axis robot stands out for its versatility and capability to perform complex tasks with precision. Selecting the right six axis robot for your automation needs can significantly influence the success of your operational processes, whether in manufacturing, assembly, or packaging.

When choosing a six axis robot, it is essential to consider several critical factors, including payload capacity, reach, speed, and precision, as these specifications directly affect the robot's performance in real-world applications. Furthermore, understanding the specific requirements of your tasks will help in identifying the ideal model that fits seamlessly into your existing infrastructure. As the demand for automation grows, so does the need for informed decision-making in acquiring the right robotic solutions.

Ultimately, the right six axis robot will enhance productivity, reduce operational costs, and improve overall quality in the production process. This guide aims to provide insights into evaluating your automation needs, exploring essential features, and ensuring that the six axis robot you choose will serve your objectives effectively for years to come.

Six axis robots are becoming increasingly essential in various industrial applications, due to their flexibility and efficiency in automating tasks. These robots are equipped with six joints, mimicking the range of motion of a human arm, allowing them to perform complex movements with precision. According to a report by MarketsandMarkets, the global industrial robotics market is projected to grow from $45.5 billion in 2020 to $73 billion by 2026, with six axis robots being a significant contributor to this growth. Their versatility makes them suitable for a wide range of applications, including welding, assembly, painting, and material handling.

One of the key advantages of six axis robots is their ability to operate in constrained spaces while executing intricate operations. For instance, in automotive manufacturing, these robots can piece together components with high accuracy, improving production efficiency. Research by the International Federation of Robotics indicates that the adoption of these robots can reduce production time by up to 30%, significantly enhancing throughput. Additionally, with advancements in AI and machine learning, six axis robots are now more capable of adapting to changing tasks and environments, making them indispensable for modern automation needs across various industries.

| Model | Payload (kg) | Reach (mm) | Application | Precision (mm) |

|---|---|---|---|---|

| A-Series | 5 | 600 | Assembly | 0.05 |

| B-Series | 10 | 800 | Welding | 0.02 |

| C-Series | 15 | 1000 | Painting | 0.1 |

| D-Series | 20 | 1200 | Pick and Place | 0.03 |

| E-Series | 8 | 500 | Packaging | 0.04 |

When selecting the right six-axis robot for your automation needs, several key factors should be carefully evaluated to ensure optimal performance and cost-efficiency. One critical consideration is the robot's payload capacity. According to a recent report by the International Federation of Robotics, the average payload capacity of six-axis robots has increased by 20% in the past five years, with many models now capable of handling loads exceeding 20 kg. This advancement allows for more adaptable production lines that can accommodate a diverse range of products and manufacturing processes.

Another essential factor is the robot's precision and repeatability, which directly impact production quality and efficiency. Industry studies have shown that six-axis robots typically achieve a repeatability of ±0.02 mm, making them suitable for intricate tasks such as assembly and welding. Choosing a robot with superior precision can lead to significant reductions in scrap rates and rework costs, ultimately enhancing overall profitability.

Furthermore, consider the ease of programming and integration into existing systems; as automation becomes more prevalent, user-friendly interfaces and compatibility with various programming languages are becoming increasingly important for manufacturers looking to streamline operations.

When selecting a six-axis robot for your automation needs, evaluating payload and reach requirements is crucial.

Payload capacity refers to the maximum weight that the robot can handle, including tools and materials.

If your application involves heavy components or intricate tooling, ensure that the robot's capacity exceeds your maximum load to prevent strain and potential damage.

Assessing your operational environment will aid in understanding the minimum and maximum payloads required.

Reach is equally important, as it determines how far the robot can extend its arm to manipulate objects within its workspace.

Consider the layout of your facility and the distance between tasks. It’s essential to select a robot with a reach that accommodates your operational workflow without requiring excessive repositioning.

Tips: When calculating your needs, add a safety margin to both payload and reach to accommodate unforeseen adjustments.

Additionally, consult with your team to understand the dynamic nature of your tasks better, ensuring you account for any variability in workload.

Regularly review and adjust your specifications based on evolving automation demands; a holistic approach will lead to more efficient operations.

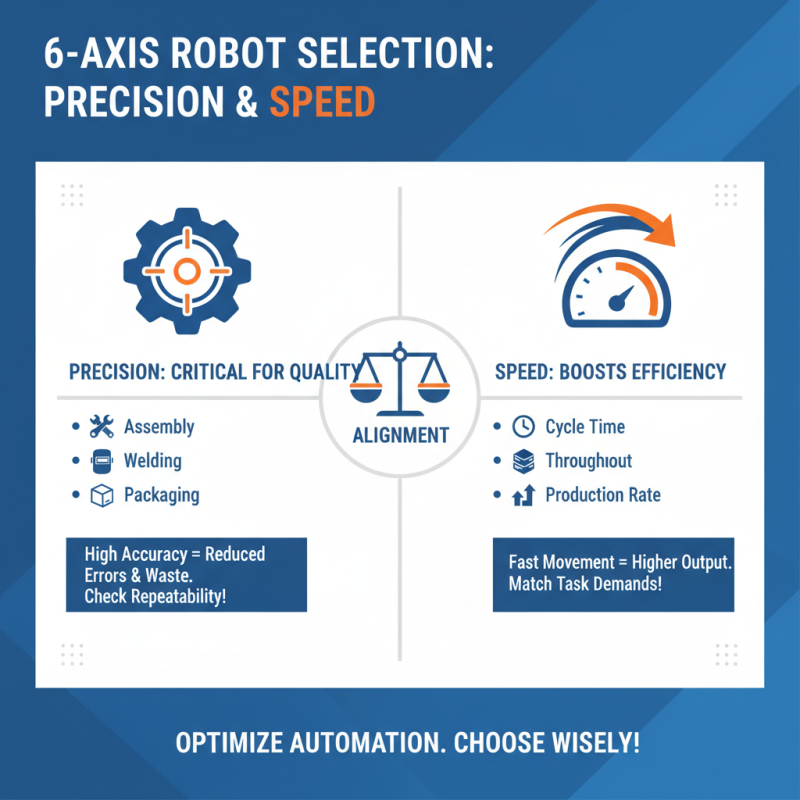

When selecting a six-axis robot for automation, precision and speed are two critical factors that must align with the specific needs of your tasks. Precision is essential for applications such as assembly, welding, or packaging, where small tolerances can significantly affect product quality and efficiency. A robot’s ability to perform movements with high accuracy not only aids in maintaining the integrity of the components but also reduces the potential for errors that could lead to production downtime or material waste. It is vital to consider the robot's repeatability specifications and determine if they meet the necessary criteria for your operations.

On the other hand, speed plays a crucial role in determining the overall throughput of your manufacturing process. A faster robot can significantly reduce cycle times, thus enhancing productivity. However, it is important to balance speed with precision, as pushing for maximum speed can sometimes compromise accuracy, especially during complex maneuvers. Evaluating the robot's speed capabilities in relation to the specific tasks it will perform helps to ensure that you select a model that can optimize both aspects effectively. Understanding the interplay between precision and speed allows for a more informed decision, tailoring the robot’s specifications to fit the demands of your automation environment seamlessly.

When selecting a six-axis robot for your automation needs, it's essential to consider how well the new system integrates with your existing infrastructure. Compatibility plays a significant role in ensuring a smooth transition and minimizing downtime. Focus on the communication protocols that your current systems use and ensure the robot can easily interface without extensive modifications. This will not only save time during implementation but also reduce unexpected costs.

**Tips:** Always request a detailed compatibility assessment from the vendor to identify potential issues early in the process. Furthermore, consider the scalability of the robot. If the robot can easily adapt to future changes or expansions in your production line, it will provide greater long-term value.

Additionally, evaluate the software capabilities of the robot. A user-friendly interface that allows for easy programming and integration with other software systems can significantly enhance operational efficiency. Look for solutions that offer simulators or emulators, enabling your team to visualize integration scenarios before actual implementation.

**Tips:** Training resources are also crucial. Ensure that the vendor provides adequate support and training to your team so everyone can effectively operate and maintain the new equipment from day one.

Taking Custom Design to New Levels

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

Fabricator

Inside Sales and Client Support Manager

Glass Handler – 1st Shift