Taking Custom Design to New Levels

PROUD TO BE PART OF THE BRIN FAMILY OF COMPANIES

OTHER BRIN LOCATIONS

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

In today’s rapidly evolving technological landscape, mobile robots are becoming indispensable assets for businesses seeking to enhance efficiency and productivity. From automating mundane tasks to revolutionizing logistics, these intelligent machines offer a plethora of applications tailored to various industries. However, with the vast array of mobile robots available on the market, selecting the right solution that aligns with your specific business needs can be a daunting task.

Understanding the capabilities and functionalities of different mobile robots is crucial for making an informed decision. Each robot varies not only in terms of design and technology but also in how they can be integrated within existing workflows to optimize operations. This introduction will explore key considerations that businesses should take into account when evaluating mobile robots, including intended applications, environmental adaptability, and cost-effectiveness. By carefully analyzing these factors, organizations can choose mobile robots that truly complement their operational goals and drive innovation within their sectors.

When selecting mobile robots for your business, it's crucial to begin with a thorough understanding of your specific requirements. This involves assessing your operational needs, the types of tasks you'd like the robots to perform, and the environment in which they will operate. For instance, if your business involves transporting goods within a warehouse, you'll need robots that are equipped with navigation and obstacle avoidance systems suitable for dynamic, unpredictable environments. Identifying whether you require autonomous navigation or remote-controlled options will also significantly impact your decision.

Additionally, consider the scalability of the mobile robots. As your business grows, your operational demands may change, necessitating the addition of more units or the need for robots that can be adapted for various applications. Therefore, it's essential to choose robots that can integrate seamlessly with your existing systems and workflows. Evaluate the compatibility of these robots with your software and hardware, as well as the support services provided by suppliers. Understanding these elements will help ensure that the mobile robots not only meet your current needs but also can evolve alongside your business objectives.

| Business Application | Robot Type | Payload Capacity | Operating Environment | Navigation Technology | Approx. Cost ($) |

|---|---|---|---|---|---|

| Warehouse Automation | Autonomous Mobile Robot (AMR) | 500 kg | Indoor | Lidar + Computer Vision | 30,000 |

| Manufacturing | Automated Guided Vehicle (AGV) | 1000 kg | Indoor/Outdoor | Magnetic Tape + Laser | 25,000 |

| Healthcare | Service Robot | 50 kg | Indoor | SLAM | 15,000 |

| Retail | Inventory Robot | 100 kg | Indoor | Computer Vision | 10,000 |

| Logistics | Delivery Robot | 300 kg | Indoor/Outdoor | GPS + Lidar | 25,000 |

Mobile robots have become integral to various industries due to their versatility and efficiency in performing tasks. Understanding the types of mobile robots available and their specific applications is essential for businesses considering their integration. According to a recent report by the International Federation of Robotics, the mobile service robot segment is expected to grow significantly, reaching nearly 33 million units worldwide by 2025. This growth reflects diverse applications ranging from logistics to healthcare.

In logistics and warehousing, autonomous mobile robots (AMRs) excel at transporting goods and materials, thereby enhancing operational efficiency. These robots utilize advanced mapping and navigation technologies, such as LIDAR and computer vision, allowing them to safely navigate dynamic environments. Research indicates that implementing AMRs can reduce operational costs by as much as 30%.

In logistics and warehousing, autonomous mobile robots (AMRs) excel at transporting goods and materials, thereby enhancing operational efficiency. These robots utilize advanced mapping and navigation technologies, such as LIDAR and computer vision, allowing them to safely navigate dynamic environments. Research indicates that implementing AMRs can reduce operational costs by as much as 30%.

In the healthcare sector, mobile robots are being utilized for tasks such as medicine delivery and disinfection, which not only streamlines processes but also minimizes human contact, particularly crucial in pandemic scenarios. A report by Markets and Markets suggests that the healthcare robotics market could reach $11 billion by 2026, driven by the increasing need for automation in various healthcare operations.

In the healthcare sector, mobile robots are being utilized for tasks such as medicine delivery and disinfection, which not only streamlines processes but also minimizes human contact, particularly crucial in pandemic scenarios. A report by Markets and Markets suggests that the healthcare robotics market could reach $11 billion by 2026, driven by the increasing need for automation in various healthcare operations.

As businesses assess their needs, they must consider the specific applications of these robots based on their operational requirements. Factors such as load capacity, navigational capabilities, and integration with existing systems are key to making informed decisions that align with business goals.

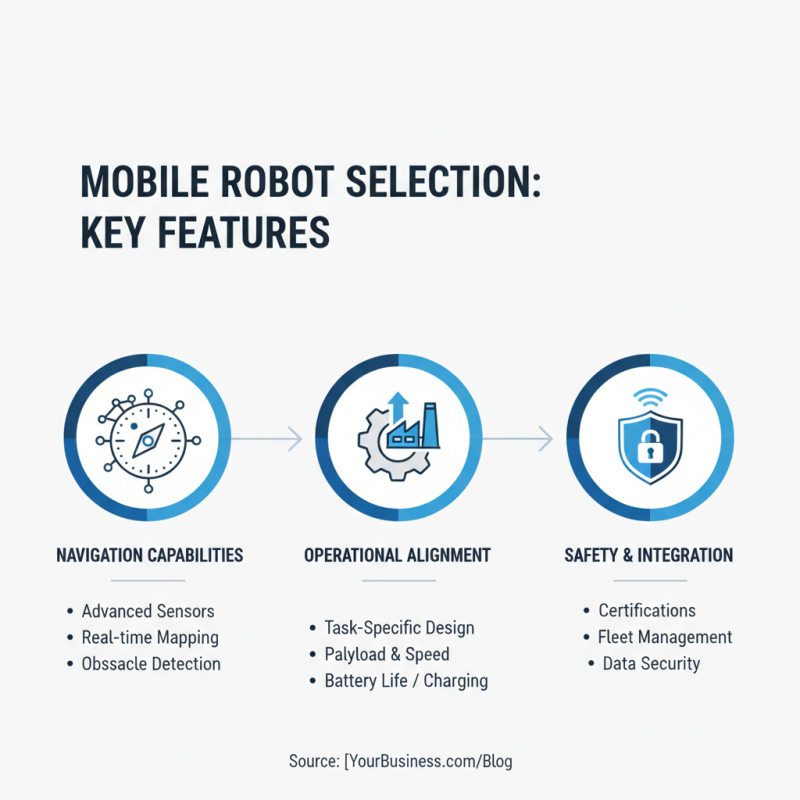

When selecting mobile robots for your business needs, it’s essential to focus on key features that align with your operational requirements. One primary aspect to consider is the robot’s navigation capabilities. Look for robots equipped with advanced sensors and mapping technologies that allow them to navigate complex environments effectively. This includes features such as obstacle detection, real-time path planning, and the ability to adapt to changing layouts, which are crucial for maximizing efficiency in dynamic settings.

Another important feature is the robot's payload capacity and versatility. Depending on your application—whether it be transporting materials, assisting in delivery, or performing specific tasks—ensure that the robot can handle the required load while maintaining stability and operational speed. Additionally, consider the ease of integration with your existing systems. A user-friendly interface and compatibility with other software or technologies can significantly enhance productivity and streamline operations within your business. Choosing a mobile robot with these key features can lead to improved workflow and better overall performance.

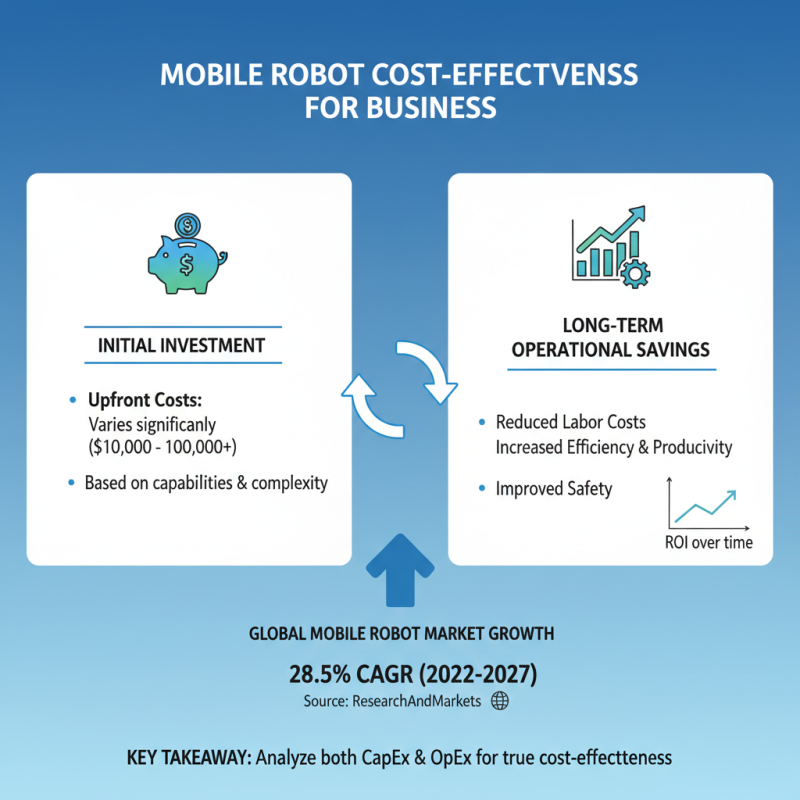

When evaluating the cost-effectiveness of mobile robots for business applications, businesses must analyze both initial investment and long-term operational savings. According to a report by ResearchAndMarkets, the global mobile robot market is projected to grow at a compound annual growth rate (CAGR) of 28.5% from 2022 to 2027, highlighting the increasing relevance of these technologies across various sectors. The upfront costs can vary significantly based on the robot's capabilities, with prices ranging from $10,000 to over $100,000, depending on the complexity and functionality required.

Furthermore, the return on investment (ROI) for implementing mobile robots can manifest in various forms. For instance, studies suggest that companies may experience labor cost reductions of up to 50% and improvements in operational efficiency by as much as 30% within the first year of integration. A report by Deloitte indicated that robotics can help alleviate labor shortages and increase productivity, with businesses reporting a 10-20% increase in throughput after automation. By strategically assessing these metrics, organizations can make informed decisions about how mobile robots align with their operational goals and budget constraints, ultimately ensuring a cost-effective adoption process.

The successful implementation and integration of mobile robots into business operations require a structured approach that aligns robotic capabilities with specific organizational needs. According to a recent report by McKinsey, automation can raise productivity by 20-25% in logistics and warehouse operations, significantly impacting both efficiency and cost reduction. However, organizations must evaluate their current workflows and identify areas where mobile robots can provide the most benefit, ensuring that robotic functions complement human efforts rather than replace them.

Once potential applications are identified, businesses should select mobile robots that seamlessly integrate with existing technology platforms. Research from the International Federation of Robotics indicates that around 75% of companies adopting automation and robotics face challenges in integrating these systems with their current operations. It is crucial to understand the interoperability of robotic systems with enterprise resource planning (ERP) and warehouse management systems (WMS) to unlock data-driven insights and enhance decision-making processes. Implementing pilot programs to test robots in real-world scenarios can also provide valuable feedback for wider deployment, ensuring that businesses can adapt and optimize their operational strategies effectively.

Taking Custom Design to New Levels

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

Fabricator

Inside Sales and Client Support Manager

Glass Handler – 1st Shift