Taking Custom Design to New Levels

PROUD TO BE PART OF THE BRIN FAMILY OF COMPANIES

OTHER BRIN LOCATIONS

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

In the world of automation, six axis robots have become essential tools for precision tasks. The demand for these machines is rising rapidly. According to a report by MarketsandMarkets, the industrial robotics market is projected to reach $70 billion by 2025. Six axis robots play a pivotal role in this growth. Their ability to perform complex movements makes them ideal for various applications, from manufacturing to assembly.

Dr. Emma Chang, a leading expert in robotics, states, "The adaptability of six axis robots makes them indispensable in today's automated environments." However, not all six axis robots excel in every task. Some may lack the precision needed for intricate operations. Others might struggle with speed in high-volume settings. This raises questions about the capabilities of different models available in the market.

When choosing a six axis robot, it is vital to assess specific needs carefully. Not every robot offers the same performance. The variation in technology and design can lead to significant differences. As industries embrace automation, understanding these nuances can define success or failure in implementation. Selecting the right six axis robot is more than a financial decision; it is a strategic one that demands reflection and foresight.

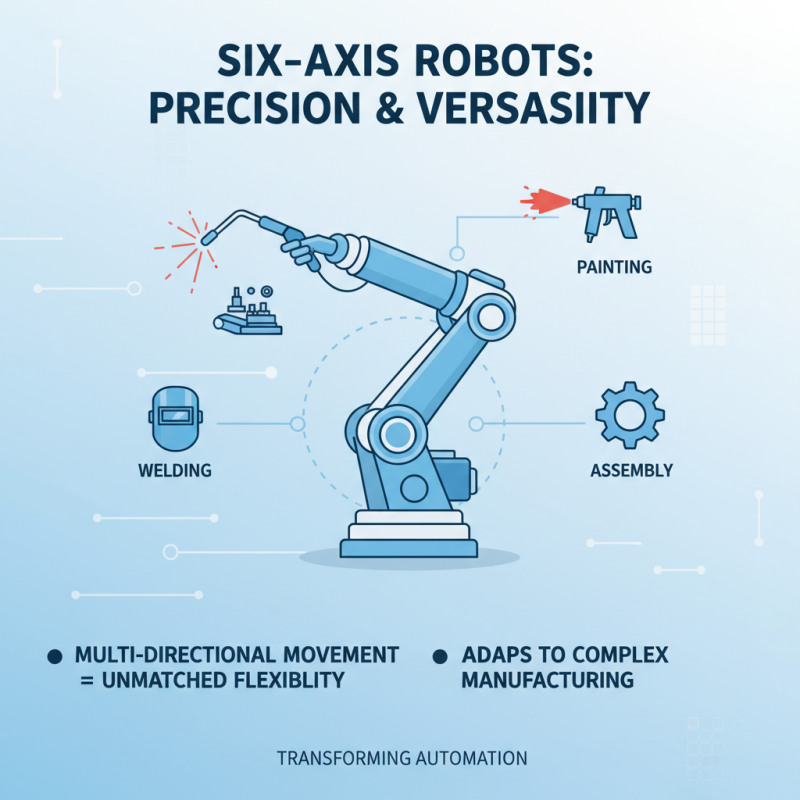

Six-axis robots have transformed the landscape of precision automation. Their ability to move in multiple directions provides unmatched flexibility. These robots excel in tasks such as welding, painting, and assembly. The versatility allows them to adapt to complex manufacturing environments.

In automotive production, six-axis robots are particularly valuable. They can navigate tight spaces with ease. This adaptability enhances production efficiency. However, programming these robots can be challenging. Misalignment in coding may lead to errors, which disrupts workflows.

Tips: When implementing six-axis robots, start with simple tasks. Gradually increase complexity as you gain experience. This approach minimizes mistakes and boosts confidence. Regular maintenance is crucial, too. Neglected robots can lead to costly downtimes.

In electronics assembly, six-axis robots ensure precision placement. They can handle delicate components without damaging them. Yet, human oversight remains essential. Operators need to watch for anomalies to maintain quality. Remember that even the best robots require careful monitoring to function optimally.

When considering six-axis robots for precision automation, key features play a crucial role. Look for robots with high repeatability, as small variations can lead to significant errors. Reports indicate that robots with a repeatability of ±0.02 mm significantly enhance process consistency. Speed also matters; faster robots can improve throughput without compromising quality.

Another important feature is payload capacity. Balancing the weight a robot can handle with its speed is essential. A robot that struggles under heavy loads may slow down production. Moreover, ease of programming should not be overlooked. User-friendly interfaces streamline setup and reduce downtime, making integration into existing systems smoother.

Tips: Ensure you assess the robot's range of motion. A wider range allows for versatile applications. Also, invest in simulation software. It helps visualize operations before implementation, saving time and resources. Regularly review your robotics system. Optimizations can lead to better performance and output quality.

Look at the maintenance aspect. Choosing a robot with easy accessibility for repairs can reduce overall maintenance costs. Remember, the right features can make a difference but think critically about your specific needs and potential limitations.

This bar chart illustrates key performance metrics for six axis robots commonly used in precision automation solutions, showcasing their payload capacity, reach, speed, repeatability, and degrees of freedom.

In 2023, six-axis robots play a crucial role in precision automation. They excel in tasks requiring high accuracy and flexibility. These machines can efficiently handle complex movements. Industries are increasingly adopting them for assembly, welding, and material handling. Their versatility makes them suitable for various applications.

However, choosing the right six-axis robot can be challenging. Different factors must be considered. For instance, payload capacity, reach, and speed are vital. Understanding the specific needs of your automation process is essential. Some organizations may overestimate their requirements, leading to inefficiencies.

Furthermore, maintenance is often overlooked. Regular check-ups ensure optimal performance. Training personnel to handle these robots is equally important. Neglecting these aspects can hinder production quality. Striking a balance between technology and human oversight is critical for success.

In the world of precision automation, six axis robots play a crucial role. These robots excel in tasks requiring intricate movements and precision. Through a comparative analysis, it becomes clear how they differ in capability and design. Each model brings unique features, catering to various industries. Some are adept at welding, while others shine in assembly tasks.

Evaluating their performance reveals strengths and weaknesses. One robot might excel in speed but falter in precision. Others may have superior load capacity but lack flexibility. These factors are essential when choosing the right robot for specific applications. A careful assessment can help avoid costly mistakes.

User feedback often highlights both innovative and frustrating experiences. Some robots face programming challenges that deter new users. Software interfaces could be more user-friendly. Additionally, maintenance issues may arise. Regular checks are crucial to ensure optimal performance. Understanding these nuances can lead to more informed decisions.

| Model | Payload Capacity (kg) | Reach (mm) | Repeatability (mm) | Weight (kg) | Control System |

|---|---|---|---|---|---|

| Model A | 10 | 600 | 0.02 | 50 | Integrated |

| Model B | 5 | 800 | 0.01 | 40 | External |

| Model C | 8 | 700 | 0.015 | 55 | Integrated |

| Model D | 12 | 650 | 0.02 | 60 | External |

| Model E | 15 | 900 | 0.025 | 70 | Integrated |

| Model F | 7 | 500 | 0.03 | 45 | External |

| Model G | 9 | 750 | 0.018 | 65 | Integrated |

| Model H | 11 | 880 | 0.02 | 75 | External |

| Model I | 14 | 720 | 0.017 | 80 | Integrated |

| Model J | 6 | 600 | 0.04 | 35 | External |

The future of six-axis robot technology is bright. Advancements in artificial intelligence and machine learning will enhance their precision and adaptability. These robots will become more intuitive, allowing for seamless integration into existing workflows. This evolution will drive greater efficiency in automation solutions.

Tips: Stay updated on AI developments. They can significantly improve robotic performance.

With an increased focus on collaborative robots (cobots), the approach to automation is changing. These robots work alongside humans, ensuring safety and efficiency. The human-robot interaction must be seamless. Yet, challenges remain. There are technical limitations in processing complex tasks together.

Tips: Invest in training for your workforce. They need to adapt to new technologies and workflows.

Sustainability is also a significant trend. Six-axis robots will be designed to reduce energy consumption and waste. Companies will need to reflect on their environmental impact. Implementing eco-friendly practices is becoming essential. Embracing these future trends requires continuous evaluation and adaptation.

Taking Custom Design to New Levels

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

Fabricator

Inside Sales and Client Support Manager

Glass Handler – 1st Shift