Taking Custom Design to New Levels

PROUD TO BE PART OF THE BRIN FAMILY OF COMPANIES

OTHER BRIN LOCATIONS

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

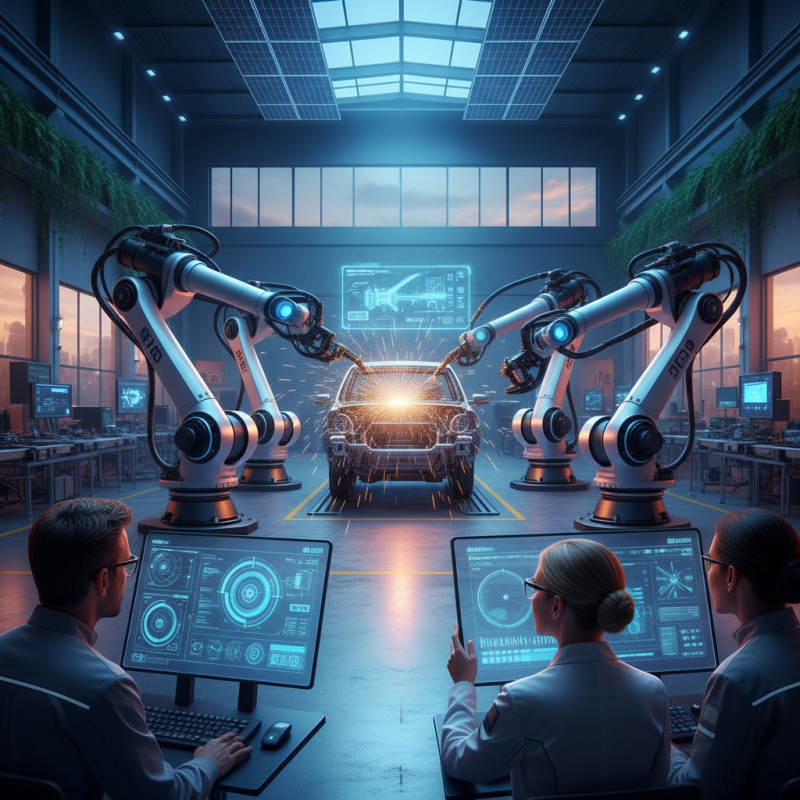

In the realm of modern manufacturing, six axis robots have become indispensable. With their versatility and precision, they transform production processes. Dr. Sarah Jenkins, a leading expert in robotics, states, "The six axis robot revolutionizes how we approach manufacturing tasks." This statement captures the essence of their impact.

Six axis robots excel in intricate tasks. They can handle welding, painting, and assembly with unparalleled accuracy. Their ability to reach difficult angles surpasses traditional robotic arms. However, the integration of these robots is not without challenges. Companies often face high initial costs and the need for skilled technicians.

Despite the hurdles, the benefits are significant. Efficiency increases, and downtime decreases. As manufacturers look to innovate, six axis robots stand at the forefront. They embody a shift towards smarter production lines. Yet, as businesses adopt these technologies, they must reflect on sustainability and workforce adaptation to ensure long-term success.

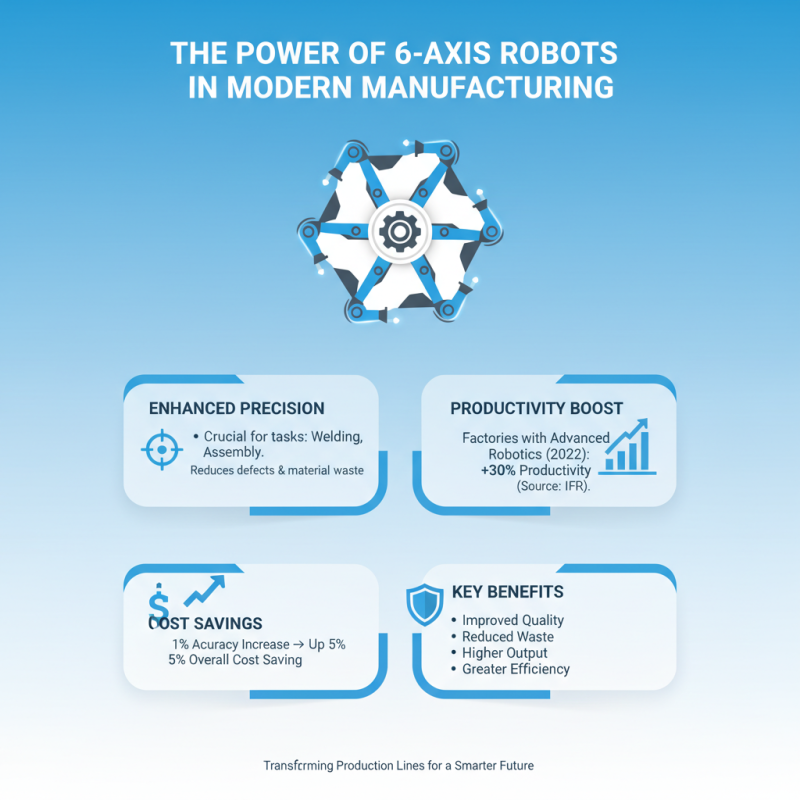

In modern manufacturing, six axis robots play a crucial role. Their ability to operate with enhanced precision transforms production lines. According to the International Federation of Robotics, factories using advanced robotics saw productivity increase by 30% in 2022. This precision is essential for tasks like welding, painting, and assembly. Improved accuracy leads to fewer defects and reduced material waste. Studies indicate that a 1% increase in precision can result in an overall cost saving of up to 5%.

Despite these advantages, precision does come with challenges. High initial costs can deter some manufacturers. Moreover, maintaining software and hardware can be demanding. Regular training for operators is necessary to maximize efficiency. Enhanced precision means more complex programming. A skilled workforce is essential to handle these systems. Companies must address this skill gap through ongoing education.

Tips: Regular audits of robotic processes can pinpoint areas for improvement. Also, consider phased investments to spread costs over time. Check for updates in technology regularly, as advancements can significantly boost efficiency. Ultimately, navigating the complexities of six axis robots requires thoughtful planning and commitment.

Automation has transformed modern manufacturing, and six-axis robots play a crucial role. These robots can perform complex tasks with precision. A report from the International Federation of Robotics noted that automation could reduce labor costs by up to 30%. This reduction in labor costs allows manufacturers to invest more in development.

Additionally, six-axis robots enhance productivity significantly. According to a study by McKinsey, companies utilizing such technology can experience up to a 50% increase in production speed. However, the initial investment can be daunting for many businesses. Some worry about limited returns in their specific industry. Balancing costs and productivity is essential.

Moreover, adapting to these robotic systems can require extensive training. Employees may face challenges as they adjust to new workflows. Despite these hurdles, the long-term benefits often outweigh the initial difficulties. Embracing six-axis robots means accepting change and managing it effectively. The future demands flexibility and readiness to innovate.

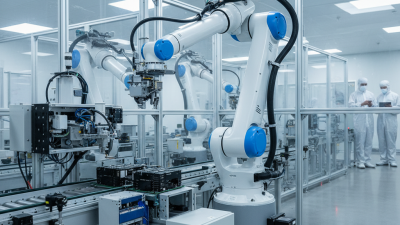

The integration of six-axis robots in modern manufacturing is transforming processes. Flexibility and adaptability are key advantages. These robots can perform various tasks, from assembly to welding, on the same production line. According to a report from the International Federation of Robotics, the demand for flexible robots grew by over 30% in the past few years. This growth stems from manufacturers needing versatile solutions to meet changing consumer demands.

Industries are adopting robots to handle diverse tasks. A study by McKinsey reveals that 60% of manufacturers are using automation for various applications. These robots can switch functions rapidly, minimizing downtime. However, challenges exist. The initial setup can be complex, requiring specialized knowledge. Not every workforce is ready for this shift. Training and adaptation are critical for smooth integration.

The precise movements of six-axis robots enhance production quality. They reduce human error and maintain a level of precision hard to achieve manually. Nevertheless, the reliance on technology calls for ongoing reflection. Companies must evaluate the balance between automation and human labor. This balance is essential for sustainable growth in the manufacturing sector.

Six-axis robots are transforming the manufacturing landscape by significantly reducing workplace hazards. These robots can perform repetitive tasks that are often dangerous for human workers. For instance, placing heavy materials in high places is now safer, as robots can handle this responsibility without risk of injury.

Tips: Ensure proper training for employees on how to interact with robots. This minimizes accidents and fosters a safer environment.

In some manufacturing settings, robots handle toxic materials. This reduces human exposure to harmful substances. While this technology enhances safety, there is a need to assess risks continuously. Human oversight remains crucial, especially in cases where machines malfunction or misinterpret commands.

Tips: Regular maintenance checks are vital for robotic systems. This can prevent malfunctions that might compromise safety.

Despite the advances in safety, it's important to question the reliance on automation. What happens if a robot encounters an unexpected situation? Would human workers know how to respond effectively? Balancing automation with human oversight is key in modern factories. This reflection promotes a safer and more efficient workplace.

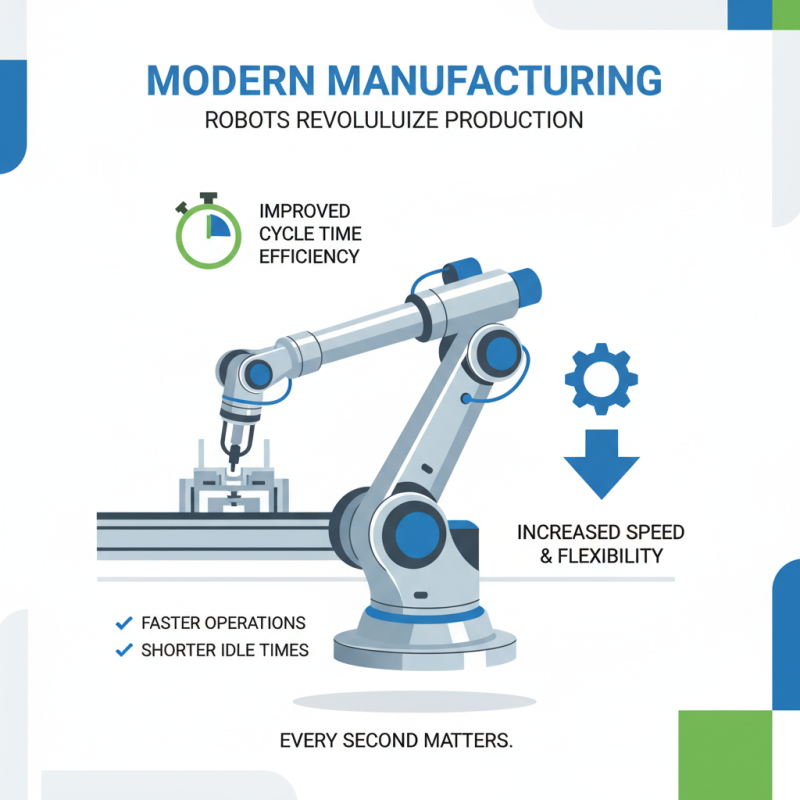

In modern manufacturing, robots are changing production dynamics. Six axis robots significantly improve cycle time efficiency. Their ability to reach multiple positions enables faster operations. This results in shorter idle times during transitions. Every second matters. Production lines benefit from their speed and flexibility.

However, implementing these robots isn't foolproof. Training staff takes time and resources. Workers may initially resist new technology. It can lead to temporary disruptions in workflow. An easy integration is not guaranteed. Businesses must reevaluate their processes frequently to ensure a smooth transition.

Real-time data analytics enhances cycle time evaluation. These robots can quickly adapt to new tasks, which boosts overall productivity. Nevertheless, constant monitoring is essential. Mistakes can occur due to programming errors or unexpected changes in the production environment. Regular updates and assessments can help refine performance. Balancing speed with accuracy is crucial for long-term success.

Taking Custom Design to New Levels

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

Fabricator

Inside Sales and Client Support Manager

Glass Handler – 1st Shift