Taking Custom Design to New Levels

PROUD TO BE PART OF THE BRIN FAMILY OF COMPANIES

OTHER BRIN LOCATIONS

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

In 2023, the landscape of industries across the globe is being reshaped by the rapid advancements in robotics technology. According to a recent report by the International Federation of Robotics, the global market for advanced robotics is projected to reach $90 billion by 2025, reflecting a compound annual growth rate of over 25%. This surge in innovation is not only streamlining manufacturing processes but also enhancing efficiency and precision in various sectors, including healthcare, logistics, and agriculture.

Dr. Emma Carter, a leading expert in the field of advanced robotics, emphasizes the transformative impact of these technologies, stating, "Advanced robotics is not just about automation; it’s about augmenting human capabilities and pushing the boundaries of what we can achieve." As industries increasingly adopt these innovations, they are not only improving productivity but also unlocking new potential in the workforce, allowing professionals to focus on more complex tasks that require critical thinking and creativity.

As we delve into the top ten advanced robotics innovations of 2023, it becomes evident that these developments are not merely trends but pivotal shifts that could redefine operational paradigms and competitive dynamics across multiple sectors. The integration of advanced robotics heralds a new era of industrial evolution, promising to enhance both economic growth and job satisfaction in an increasingly automated world.

In 2023, the landscape of manufacturing processes is significantly reshaped by advanced robotics innovations that enhance efficiency and precision. These technologies are not only streamlining production lines but also improving safety and reducing costs. Collaborative robots, or cobots, are playing a major role, working alongside human operators to augment their capabilities. By taking on repetitive or hazardous tasks, these robots enable workers to focus on more complex problem-solving activities, enhancing overall productivity in manufacturing settings.

Automation systems equipped with the latest machine learning algorithms allow for real-time data analysis, helping manufacturers to predict maintenance needs and minimize downtime. The use of robotic arms with advanced sensory technology enables intricate assembly tasks that were previously impossible, further pushing the boundaries of what manufacturing can achieve. This shift towards integrating smart robotics with traditional manufacturing significantly alters workflows and enhances output quality.

Tips: When considering the implementation of robotics in manufacturing, start with a thorough assessment of the current processes to identify automation opportunities. Engage with employees to understand their needs and concerns regarding new technologies. This collaboration will foster a positive transition and maximize the benefits of robotics in your operations. Implementing a training program for staff on working alongside robotic systems is also crucial to ensure smooth integration and drive innovation success.

| Innovation | Description | Industry Impact | Key Feature | Expected Growth (%) |

|---|---|---|---|---|

| Collaborative Robots | Robots designed to work alongside humans in shared spaces. | Manufacturing | Enhanced safety features and intuitive controls. | 22% |

| Autonomous Mobile Robots | Robots that navigate and perform tasks without human intervention. | Warehousing and Logistics | Real-time obstacle avoidance and path planning. | 30% |

| Robotic Process Automation | Software robots to automate routine tasks and workflows. | Finance and IT | Integration with AI for decision making. | 26% |

| Drones for Inventory Management | Drones used for stocktaking and monitoring in real-time. | Retail and Warehousing | Automated aerial scanning and data collection. | 35% |

| Advanced Robotic Arms | Highly flexible robotic arms for precise tasks. | Manufacturing and Assembly | High precision and customizable tooling. | 28% |

| Exoskeletons | Wearable robots that enhance human strength and endurance. | Healthcare and Manufacturing | Support for injured workers and ergonomic assistance. | 18% |

| AI-Powered Quality Inspection | Using AI to detect defects in manufacturing processes. | Quality Control | Machine learning algorithms for enhanced detection. | 30% |

| Smart Grippers | Intelligent grippers that adapt to different objects. | Manufacturing and Logistics | Soft robotics technology for enhanced dexterity. | 25% |

| Humanoid Robots | Robots designed to mimic human actions and interactions. | Service Industry | Responsive to social cues and capable of conversation. | 20% |

| Virtual Reality Training Robots | Robots integrated with VR to train workers in simulations. | Training and Development | Immersive learning experiences and real-time feedback. | 15% |

The intersection of artificial intelligence (AI) and advanced robotics is significantly transforming industries in 2023. AI technologies, such as machine learning and computer vision, are enhancing the capabilities of robots, making them more intelligent and adaptive. According to a report by McKinsey & Company, companies that have integrated AI into their robotic systems have witnessed productivity improvements of up to 30%. This advancement not only improves operational efficiency but also reduces downtime by enabling predictive maintenance—a critical factor in industries like manufacturing and logistics.

AI-powered robotics systems can analyze vast amounts of data in real-time, allowing for smarter decision-making. In sectors such as healthcare, robotics integrated with AI can assist in surgeries with precision, thus minimizing human error and optimizing patient outcomes. Moreover, a study by Deloitte indicates that AI-driven automation could result in an economic boost, potentially adding $15.7 trillion to the global economy by 2030. As industries continue to embrace these innovations, the synergy between AI and robotics is expected to play a pivotal role in creating more efficient and productive environments.

Tips: When exploring AI integration in robotics, consider starting with pilot projects to assess the technology's impact on your specific operations. Additionally, invest in training for your workforce to ensure seamless collaboration between humans and AI-driven machines. This foundational approach can facilitate a smoother transition into a more automated and data-driven future.

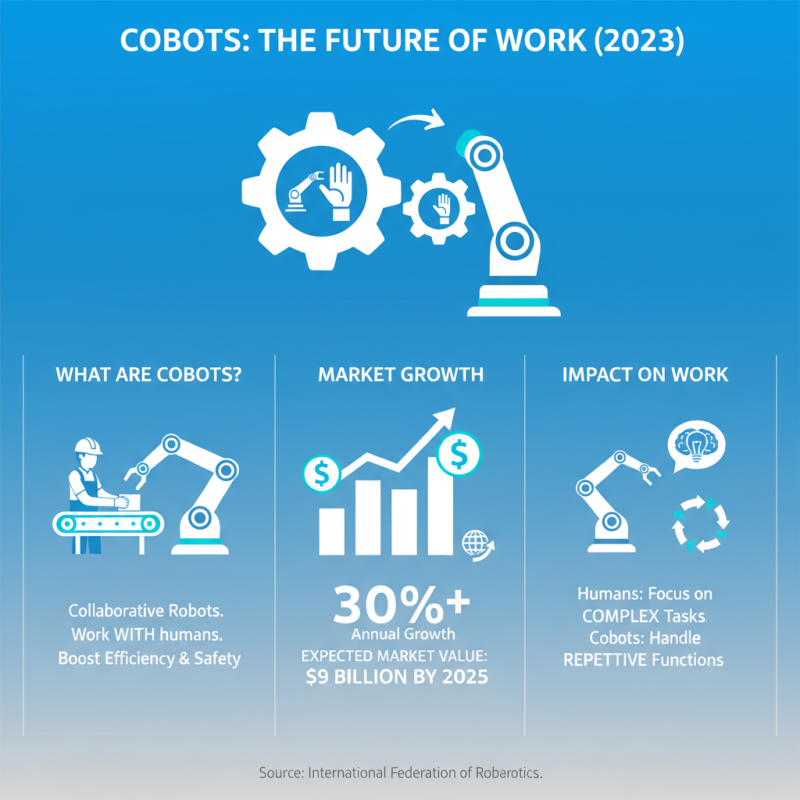

In 2023, collaborative robots, or cobots, are revolutionizing industries by enhancing interactions between humans and machines. Unlike traditional industrial robots, which operate in isolation, cobots are designed to work alongside human workers, improving efficiency and safety in the workplace. According to a recent report from the International Federation of Robotics, the market for collaborative robots is expected to grow by over 30% annually, reaching a valuation of approximately $9 billion by 2025. This surge indicates a significant shift toward integrating robots into everyday work processes, allowing workers to focus on more complex tasks while cobots handle repetitive functions.

The implementation of cobots not only boosts productivity but also fosters a safer working environment. A study conducted by the Robotics Business Review highlighted that organizations integrating collaborative systems reported a 50% reduction in workplace accidents related to repetitive strain. By sharing tasks with human operators, cobots mitigate risks and enhance overall workforce ergonomics. Facilities are more adaptable, resulting in streamlined operations and improved product quality.

**Tips:** When considering integrating cobots into your operations, start small by identifying specific tasks that can be effectively shared between human workers and robots. Prioritize training for your staff on how to work alongside these systems to maximize collaboration and efficiency. Additionally, it's vital to continually assess the impact of cobot integration on productivity and employee well-being to ensure sustainable growth.

The emergence of autonomous mobile robots (AMRs) is fundamentally reshaping supply chain management in 2023. These innovative machines are designed to navigate complex environments, making them essential for warehouses and distribution centers where efficiency is paramount. By automating material handling, AMRs significantly reduce human error and operational costs while enhancing productivity. The ability to operate around the clock without breaks allows companies to streamline operations and meet the rising demand for faster delivery services.

Tips for integrating autonomous mobile robots into your supply chain include conducting a thorough analysis of your current processes to identify areas where robotics can provide the most impact. Training staff to work alongside these robots is also crucial; embracing the technology rather than fearing it can lead to a smoother transition. Additionally, regularly updating software and maintaining the equipment will ensure that the AMRs operate at peak efficiency and adapt to changes in inventory or layout.

As industries continue to embrace digital transformation, AMRs are becoming indispensable tools in navigating the complexities of supply chains. Companies that successfully implement these robotics innovations not only benefit from increased efficiency but also position themselves competitively in an ever-evolving marketplace. Exploring partnerships with robotics experts can provide valuable insights into optimizing these technologies for your specific needs, driving continuous improvements in operational workflows.

Advanced robotics is revolutionizing the healthcare sector, bringing forth innovations that significantly enhance patient care and surgical procedures. One of the key advancements is the integration of robotic systems in minimally invasive surgeries. These systems allow surgeons to perform intricate procedures with unparalleled precision, reducing recovery times and improving patient outcomes. By utilizing robotic arms, surgeons can navigate through the human body with extreme accuracy, minimizing damage to surrounding tissues and ensuring that patients can return to their daily lives more quickly.

Additionally, robotic devices are increasingly used in rehabilitation settings, providing personalized therapy that adapts to individual patient needs. These robots can assist patients in regaining mobility by offering consistent support and feedback throughout the rehabilitation process. The deployment of robotics in this area not only enhances the effectiveness of physical therapy but also alleviates the strain on healthcare professionals, allowing them to focus on more complex tasks.

Tips for integrating robotics into healthcare settings include investing in staff training to ensure proper use and maintenance of robotic systems. Emphasizing a multidisciplinary approach can also expedite the implementation of these technologies, fostering collaboration between engineers, healthcare providers, and patients. Moreover, continuously gathering patient feedback post-implementation is crucial for refining robotic applications and enhancing overall care quality.

Taking Custom Design to New Levels

Brin Glass Company | Minneapolis, MN

St. Germain’s Glass | Duluth, MN

Heartland Glass | Waite Park, MN

Fabricator

Inside Sales and Client Support Manager

Glass Handler – 1st Shift